Furnace Structure | - Double layer steel structure with air cooling to keep case temperature <65°C

- High purity fibrous alumina insulation with the Special coating to ensure max. energy saving

|

Power | 6KW |

Voltage | AC 208-240V Single Phase, 50/60 Hz |

Max. Temperature | 1200°C(<1 hr) |

Continuous Temperature | 1100°C for each zone |

Max. Heating Rate | <= 20°C/min. |

Processing Tube | - High purity quartz tube with 1200oC max. working temperature

- Size: OD: 80 mm,x ID. 72 mm x 1000mm Length

- Upgrade note:( Processing tube can be replaced by mullite tube from 60 mm OD to 100 mm OD at extra cost, then furnace can be used up to 1250°C )

|

Heating Zone length | 440mm (single zone) |

Constant Temperature Zone | 150mm (+/-1°C) |

Temperature Accuracy | +/- 1°C |

Temperature Controller | - MET certified 30 programmable segments for precise control of heating rate, cooling rate and dwell time.

- Built in PID Auto-Tune function with overheating & broken thermocouple broken protection.

- Over temperature protection and alarm allows for operation without attendant(s).

- +/- 1 ºC temperature accuracy.

- RS485 Communication Port.

- Advanced Temperature Control (Optional)

- MTS02-Y Temperature control software kit (for YD518P series controllers) + 15" laptop package is available at the options bar. Click for the detail information about the MTS02-Y software kit.

- You may upgrade the temperature controller to the Eurotherm 3504 Temperature Controller which is fully compatible with LabVIEW. This package includes a Eurotherm 3504 programmer, a communication cable (RS485 - USB) and a software CD. Click the pic below to view the full spec of Eurotherm 3504 temperature controller.

|

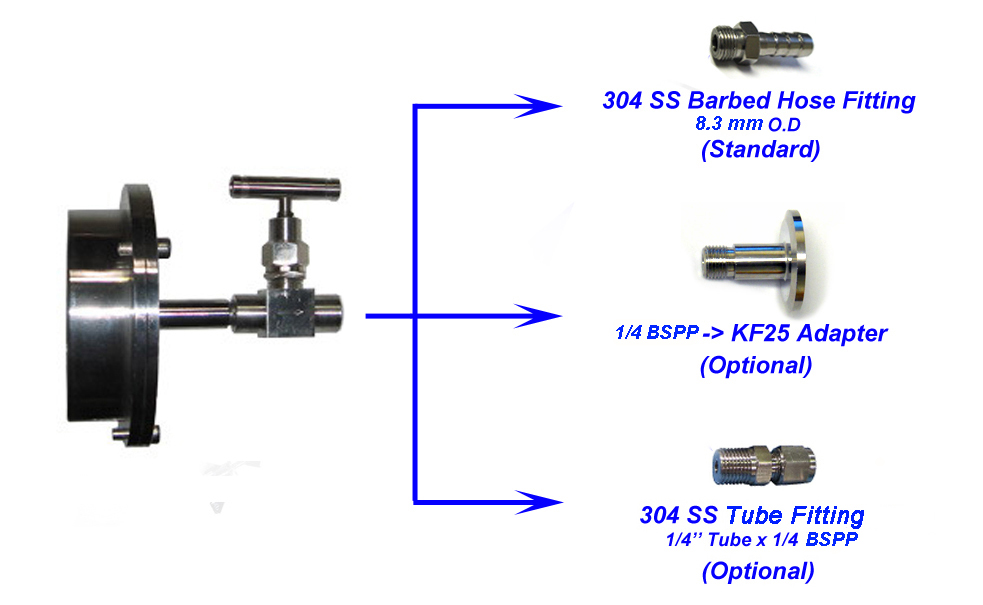

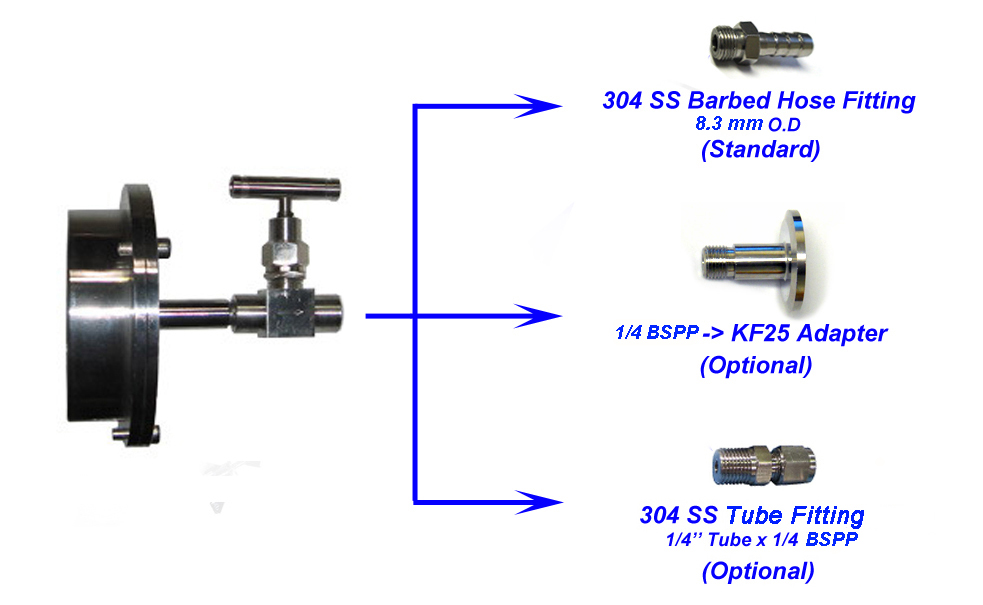

Vacuum & Fitting Ports

| |

Vacuum Level | 10E-2 Torr by mechanical vacuum pump. 10E-5 Torr by molecular pump. Leak rate < 5 mTorr / min. |

Heating Element | 1300°C Fe-Cr-Al Alloy doped by Mo |

Dimensions | 550mm(L) x 380mm(W) x 520mm(H) exclude mobile cart 600mm(L) x 600mm(W) x 1200(H) install with mobile cart |

Net Weight | About 80kg (excluding mobile cart) |

Shipping size | 48"(L) x 40" (W) x 72''(H) |

Shipping weight | 400lbs |

Warranty | One year limited warranty with lifetime support (Consumable parts such as processing tubes and o-rings are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control (Optional) | |

Compliance | - CE Certified

- All electric components ( >24V) are UL / MET / CSA certified

- The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost. ( please click marks below to learn details )

|

| |

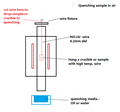

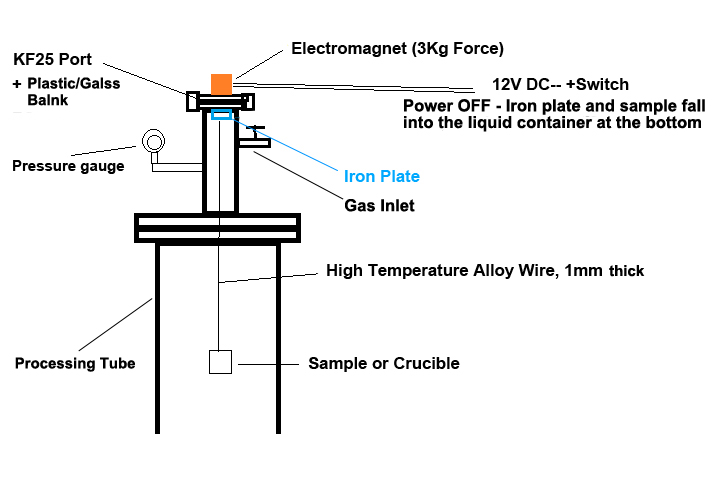

Application Notes

( We may help you to build customized flange to meet your application at extra cost ) | - Please click picture below to learn how to quenching sample in gas flow and vacuum

The furnace ca be modified into an HPCVD ( hybrid physical-chemical vapor deposition ) furnace via DIY a sample susceptor ( click picture below-right to see how )

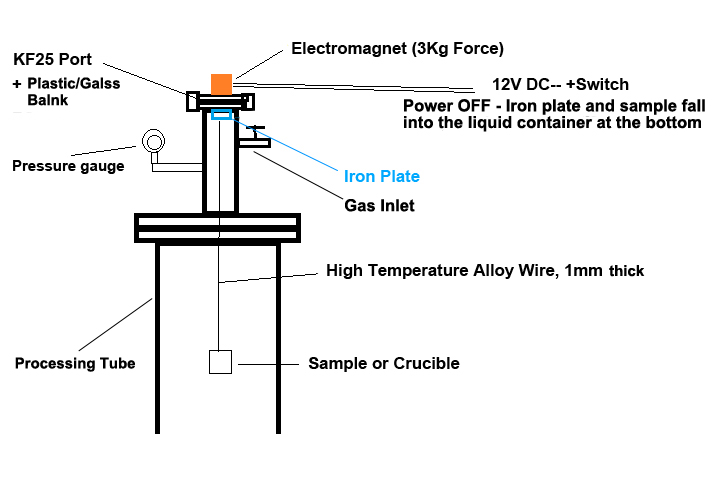

- Approach#1: Traditional wire cut and free-falling

- Approach#2: Electromagnetic release and free-falling. Please contact us for the customization of this feature.

|

Warning

Click here to learn the installation of a gas regulator | - The tube furnaces with quartz tube are designed for using under vacuum and low pressure <0.2 bars / 3 psi / 0.02 MPa

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°C

|

Operation Instructions |

|