Annealsys manufactures Rapid Thermal Processing (RTP) and chemical vapor deposition (CVD/ALD) systems. Our customers are Research and Development laboratories and companies for production applications. The privately owned company Annealsys was established in 2004 in Montpellier, South of France. Annealsys provides outstanding technical and process customer service through a worldwide sales and service organization.

Our philosophy involves:

· Building up a long-term relationship with our customers

· Provide high reliability and high quality tools

· Insure low cost of ownership

· Offer support and service excellence

To achieve this goal, we set up a worldwide sales and customer service network.

Annealsys RTP and RTCVD versatile systems

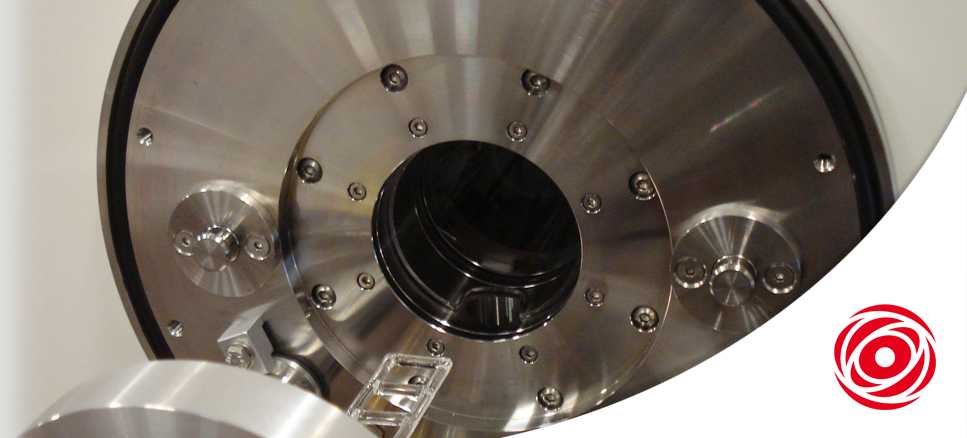

Annealsys Rapid Thermal Processing (RTP) furnaces can address various applications with an extended temperature range and vacuum capability.

The infrared lamp furnaces can perform annealing up to 1450°C and for duration up to 1 hour at 1200°C. The high temperature Zenith system can run process at 2000°C for 1 hour.

Applications include Rapid Thermal Annealing (RTA) processes like ohmic contact annealing and implantation annealing as well as Rapid Thermal Chemical Vapor Deposition (RTCVD) of graphene or hexagonal Boron Nitride (h-BN).

These versatile RTP systems can process samples from few mm² up to 200 mm diameter with manual loading or cassette to cassette robot handling for production, including customized solutions for processing compound semiconductor wafers with susceptors.

DLI-CVD (Chemical Vapor Deposition) / DLI-ALD

Annealsys Direct Liquid Injection (DLI) deposition systems are using state of the art DLI vaporizers allowing the utilization of low vapor pressure and thermally unstable chemical precursors.

Annealsys is developing processes for the deposition of multi metallic oxides, metal, transition metal nitrides layers and also 2D materials including graphene, hexagonal boron nitride and transition metal dichalcogenides (TMDs).

Machines are available for substrates up to 50 mm, 100 mm or 200 mm diameter.

Small 3D parts (few centimeters size) can be processed in the 50 mm machine. Our DLI deposition systems offer multiprocess capabilities inside the same process chamber: DLI-CVD, DLI-ALD, MOCVD, pulse pressure CVD and even in-situ rapid thermal processing (RTP) for the MC-050.