Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

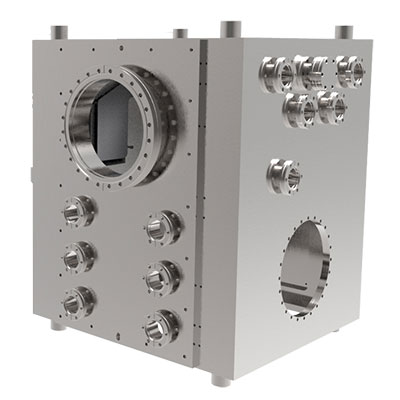

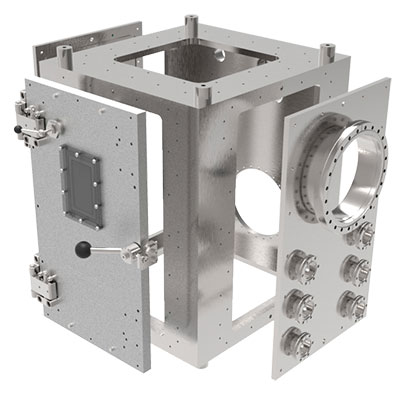

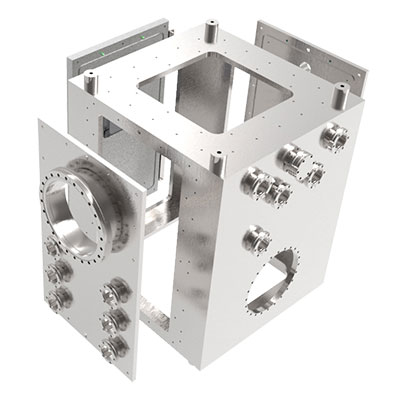

PRO Line PVD 200 – Versatile Sputtering, Electron Beam, & Thermal Evaporation Deposition Platform

Description

Overview

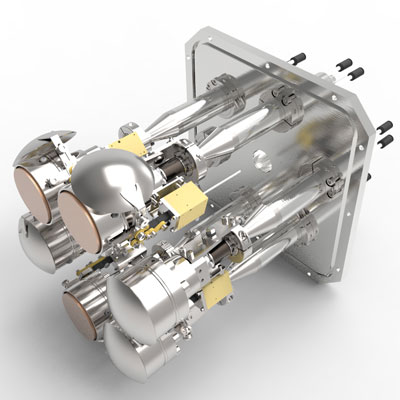

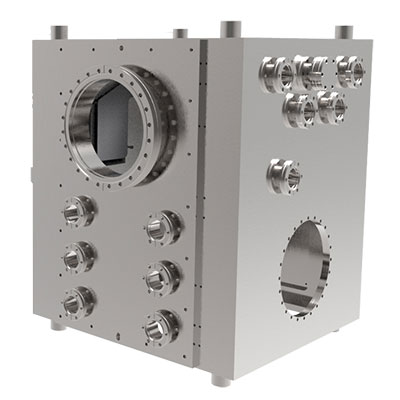

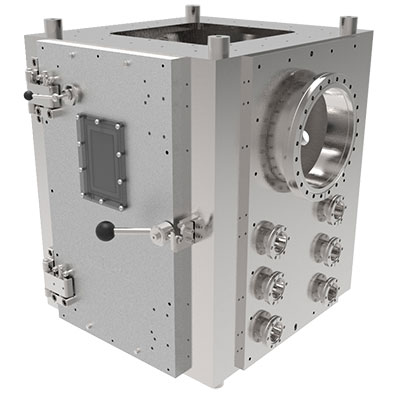

The Kurt J. Lesker Company® PRO Line PVD 200 is a modular, full featured thin film deposition system allowing 8" wafer transfer, up to 8 sputter cathodes and eKLipse advanced control software. With more than 500 units in service worldwide, the PVD series is a proven, robust, and versatile design consisting of the PVD 75 and 200 platforms. The PRO Line PVD 200 builds on the successes of the original design with improved system base pressures and pump down times. A technically superior chamber design, an industry best software control system with advanced programming capability, automatic substrate loading, and numerous features for optimized thin film performance are a few of the key advantages offered in this innovative, best of class design.

The PRO Line PVD 200 is compatible with the following techniques:

- Thermal Evaporation (up to six 4" individual boats)

- Torus® Magnetron Sputtering sources (up to eight 2" or 3" sources)

- Electron Beam Evaporation Source (4 pocket 8cc, 8 pocket 12cc, 6 pocket 20cc)

- LTE10 Organic deposition sources (up to two)

- Combinations of the above techniques are also available.

- Custom configurations are available upon request

KJLC's software allows user friendly recipe creation along with a reliable, uninterruptable processing module that allows process completion, regardless of the state of the computer user interface. For more information on this intuitive, unique, and reliable software package, please see the

Features

Modular Process Chamber

|

Vacuum Pumping & Gauging

|  |

SafetyFully enclosed system electronics rack.

*System dimensions and mounting dependent on options selected. |

Pumping OptionsProcess Equipment OptionsSubstrate Options

HV Pumping Options

|  | ||||||||||||||||||

| HV Valves

| ||||||||||||||||||

Upstream Pressure Control

|  | ||||||||||||||||||

| Magnetron Sputtering Source Power Supplies

| ||||||||||||||||||

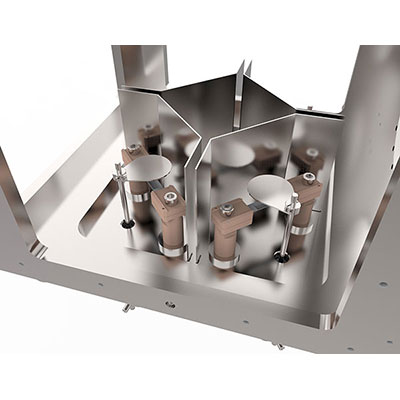

Torus® Magnetron Sputtering Source (Up to eight)

For more information on our new Mag Keeper sources please see the following link. | |||||||||||||||||||

| Electron Beam Evaporation Source | ||||||||||||||||||

Thermal Evaporation Source

| |||||||||||||||||||

| Standard Substrate Fixtures

| ||||||||||||||||||

Ion Source

|  | ||||||||||||||||||

| Reactive Depositions

| ||||||||||||||||||

Single Substrate Load Lock

| |||||||||||||||||||

Pumping:The PRO Line PVD 200 offers four types of high vacuum pumping on its process chamber, a Pfeiffer 790 L/s turbomolecular pump (standard), as well as an optional 1250L/s Pfeiffer turbomolecular pump, Brooks CTI-8F 1500 L/s, or 3000 L/s cryo pump. The Pfeiffer turbomolecular pumps being a good choice for overall cost effective high quality pumping particularly for sputtering applications. The Brook CTI cryo pumps find use in applications that require the lowest vacuum possible, particularly for thermal evaporation and electron beam applications. The chart to the right demonstrates average expected pumping performance by pump type for an outfitted PRO Line PVD 200 process chamber that is clean and dry with (5) Torus 3" Mag-keeper sources installed and a 3' long 1.5" metal flex bellows roughing line. | Pump data for a clean dry and empty PRO Line PVD 200. Pumping performance is depending on chamber conditions and components installed. | ||||||||||||||||||

| The PVD 200 was re-designed to mount the high vacuum valve directly to the process chamber without the 4" half nipple and accommodates a larger 790 L/s pump, 1250L/s pump, or CTI8 pump. This allows the PRO Line PVD 200 to reach lower base pressures and faster pumpdown times than similarly equipped systems. The CTI10 Cryo pump does require a pumping port nipple and will limit some options. | ||||||||||||||||||

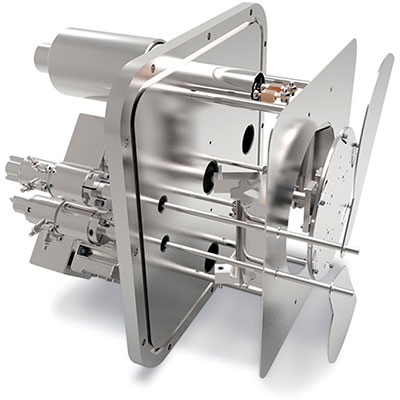

Deposition:The PRO Line PVD 200 is one of Kurt J. Lesker's most versatile thin film deposition systems offering single and multi-technique deposition options including thermal evaporation, magnetron sputtering (Torus), and electron beam. Only KJLC offers Mag-Keeper sputter sources with zero o-rings in the cathode body and a magnetically coupled target to allow for easy target changes. Our "patent pending" cooling well design enables operation at power densities up to 200 watts/.in2. This cathode is designed to sputter up to a 0.375" thick targets. Without a hold down clamp or dark space shield this cathode is capable of running as low as ≤ 1mTorr (material dependent). The unique dome shutter design eliminates the need for additional cross contamination shielding required with standard flip or swing shutters. To learn more about sputtering rates and uniformity, click here. |  | ||||||||||||||||||

KJLC E-beam sources are also designed to eliminate unnecessary o-rings, seals, and feedthroughs to lower pumpdown times and provide excellent base pressures. Only three feedthrough's are required for the KJLC E-beam source and there is no dynamic water to vacuum o-ring seal in this design which greatly reduces the risk of a water leak in the vacuum chamber. | |||||||||||||||||||

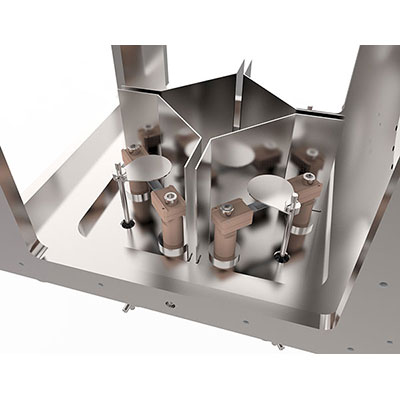

Thermal evaporation sources typically centered on the substrate fixture have been moved to the outer edges of the fixture to allow for better uniformities. The fixtures allow a source adjustment of up to an inch to allow for optimization to a particular application. |  | ||||||||||||||||||

Typical Deposition Uniformities | The PRO Line PVD 200 has been designed for optimal uniformities and allows ultimate base pressures otherwise not achievable in modular R&D systems until now. The chart to the left shows average expected uniformity by deposition type and substrate wafer diameter. Thickness measurements were made using a Profilometer or spectral reflectometer. The actual uniformity achievable will be a function of the final configuration of the system and process parameters. | ||||||||||||||||||

Torus® sources are operated at typical sputtering pressures (< 20 mTorr) and utilize Si wafers for deposition. SiO2 Target run with RF Power, film thickness >=500Å. Al Target run with DC Power, film thickness >=1500Å. Ni Target run with High Strength Torus® & DC Power, film thickness >=1500Å. KJLC electron beam deposition runs utilize Si wafers for deposition. Ti evaporant material with film thickness >=1500Å.

|