Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Five Zones Split Vertical Tube Furnace with 4" Quartz Tube & SS Vacuum Flanges - OTF-1200X-VT-V-100

Description

OTF-1200X-VT-V-100 is CE certified five zones split Vertical Tube Furnace with vacuum sealed 100mm (4") diameter quartz tube, which can achieve faster sample heating and quenching under vacuum or flowing gas. Precision temperature controller can provide 30 heating and cooling segments with +/- 1 oC accuracy. It is an idea furnace for making quenching test and nano-powder

SPECIFICATIONS

| Furnace Casing | Double layer steel structure with air cooling to keep case temperature > 65oC |

Power | 6KW |

Voltage | AC 208-240V Single Phase, 50/60 Hz |

Max. Temperature | 1200oC < 1 hrs |

Continuous Temperature | 1100oC < continuous |

Max. Heating Rate | <= 20oC /min |

Tube Size and Materials |

|

Heating Zone length |

|

| Equal temperature zone |

|

Temperature Controllers |

|

Laptop, software & WiFi Control(Optional) |

|

| Vacuum Seal |

|

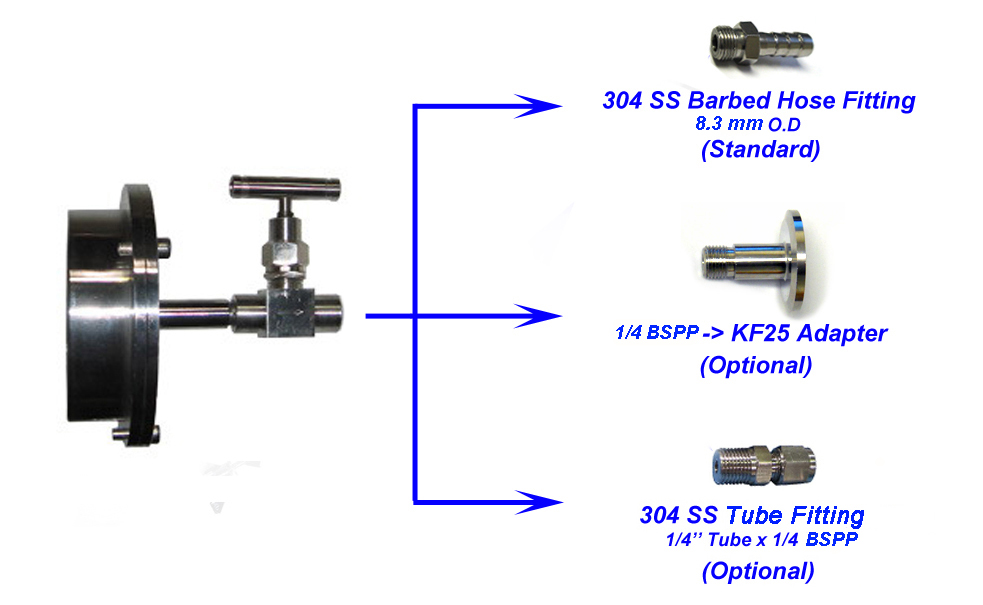

Fitting Ports |

|

Vacuum Level | 0.1torr (depends on the vacuum pump) |

Heating Element | Fe-Cr-Al Alloy doped by Mo |

Dimension | 1100mm x 450mm x 670mm ( exclude mobile cart ) 1200mm (H) x 600mm (W) x 600mm (W) install with mobile cart |

Net Weight | about 180Kg (excluding mobile cart) |

Shipping Package Size after Crating | 65"x40"x80" |

Shipping weight | 675 lbs |

Warranty |

|

Compliance |

|

Application Notes |

|

Operation Instructions |