Description

Part Number: OTF-1200X-S-VT

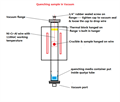

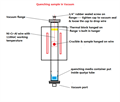

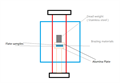

OTF-1200X-S-VT is a compact-split Vertical Tube Furnace with vacuum sealed 1“, 2" or 2.36"(60mm) diameter quartz tube. It provides fast heating and quenching as well as the capability to heat samples under vacuum or flowing gas atmospheres. A precision temperature controller can provide up to 30 segments of heating, cooling, and dwelling steps with +/- 1 oC accuracy. It is an ideal furnace for carrying out quenching tests. New!!! the electric components of the 220V version OTF-1200X-S-VTare UL/CSA certified, and the 220V version is ready to pass UL or CSA certification (UL61010 or SPE1000) on customer side at customer cost. (01/22/2014)

SPECIFICATIONS

| Furnace Casing | - Double layer steel structure with air cooling

- Split door design for easy installation of tube

- High purity Al2O3 fibrous insulation designed for maximum energy saving

|

Power | 1.2KW |

Voltage | AC 110V or 220V Single Phase, 50/60 Hz |

Max. Temperature | 1100oC |

Continuous Temperature | 1000oC |

Max. Heating Rate | <= 20 oC /min |

Tube Size and Materials | Select the tube size:

25mm O.D x 20mm I.D x 610mm L

50mm O.D x 44mm I.D x 610mm L |

Heating Zone Length | 200mm (single zone) |

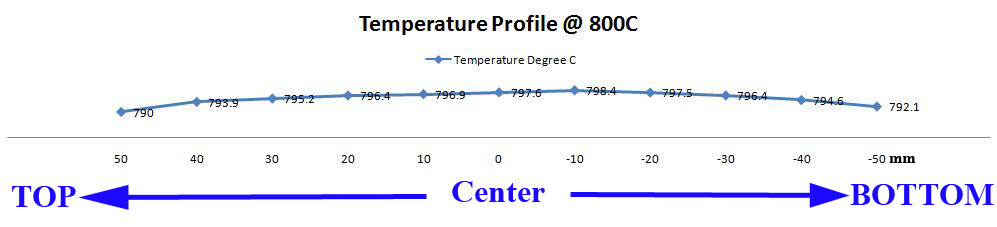

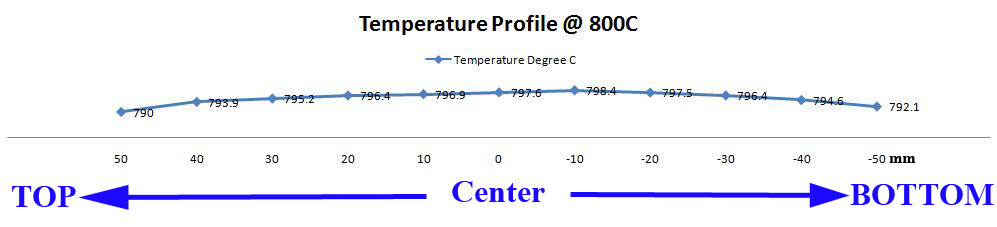

| Constant Heating Zone | 100mm (+/-2oC)

|

Temperature Controller

| - 30 programmable segments for precise control of heating rate, cooling rate and dwell time.

- Built in PID Auto-Tune function with overheating & broken thermocouple protection.

- Over temperature protection and alarm allows for operation without attendant(s).

- +/- 1 ºC temperature accuracy.

|

| Heating Elements | Fe-Cr-Al Alloy doped by Mo |

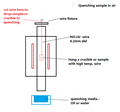

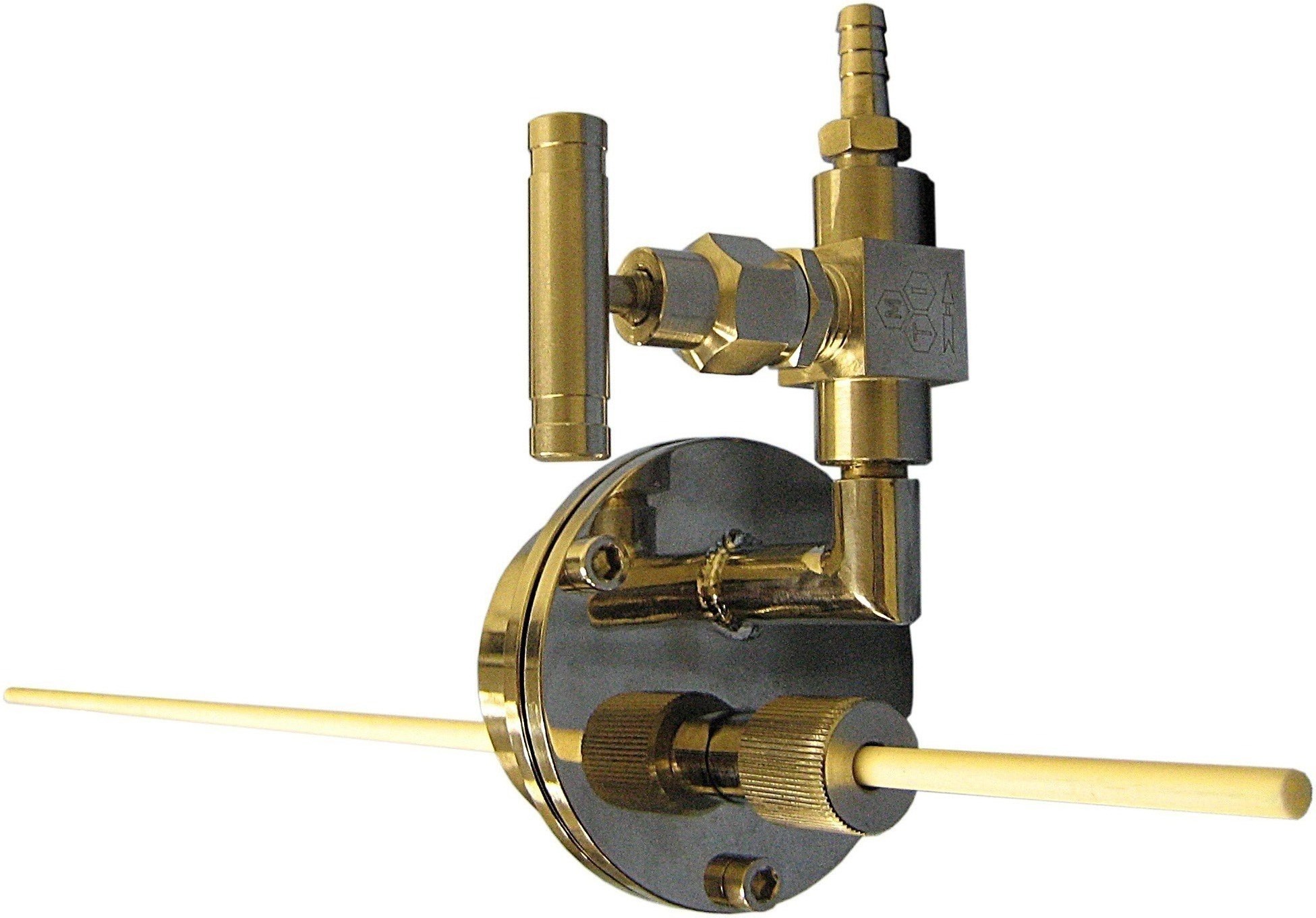

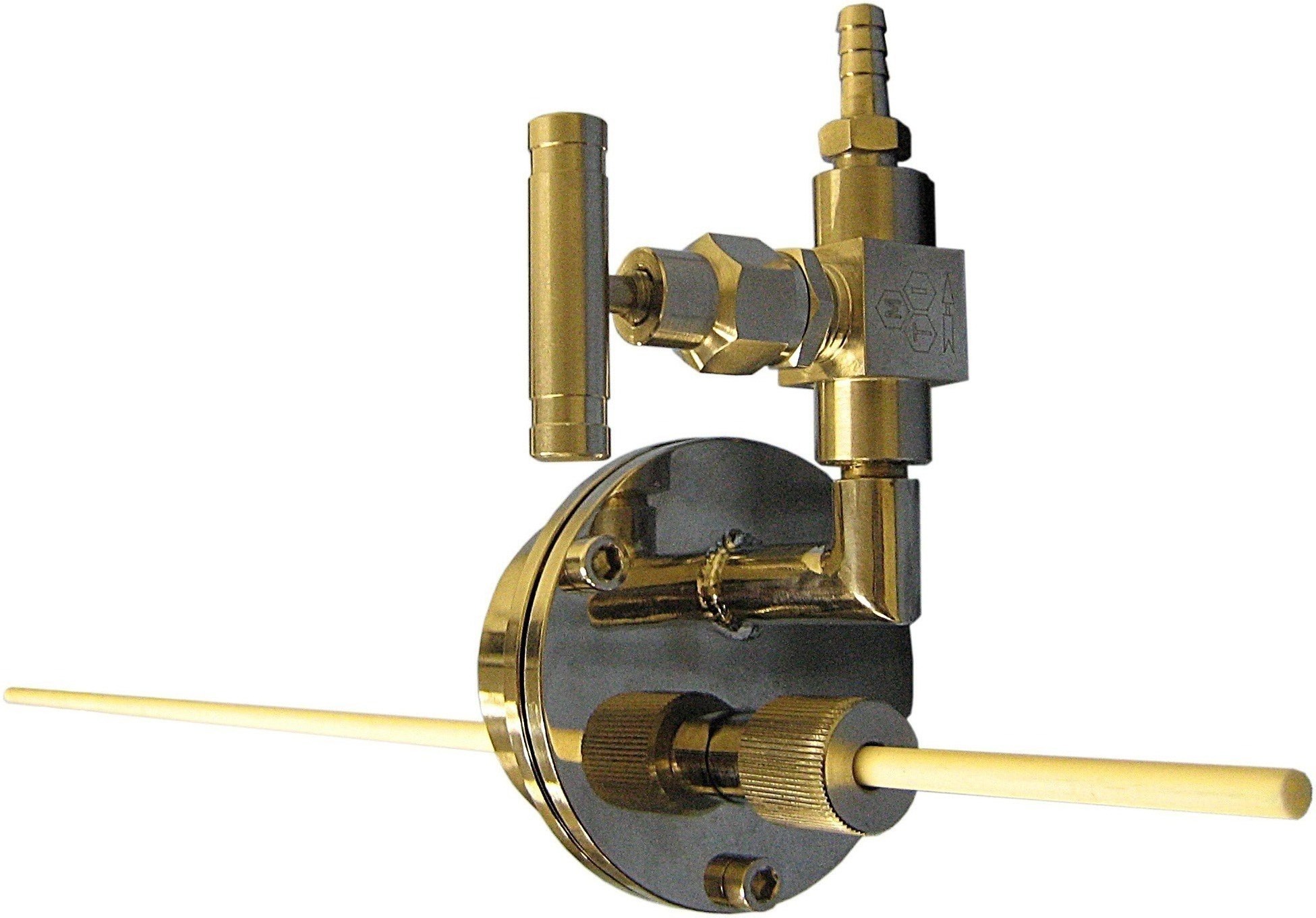

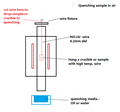

| Vacuum Sealing | - Two stainless steel flanges with vacuum gauge and valves included

- A hook ring is welded inside of the top flange for hanging samples or crucibles by wire

- You may order an optional 2" flange (for 50mm O.D. tubes only) with 1/4" feedthrough port for inserting a thermocouple or rod

|

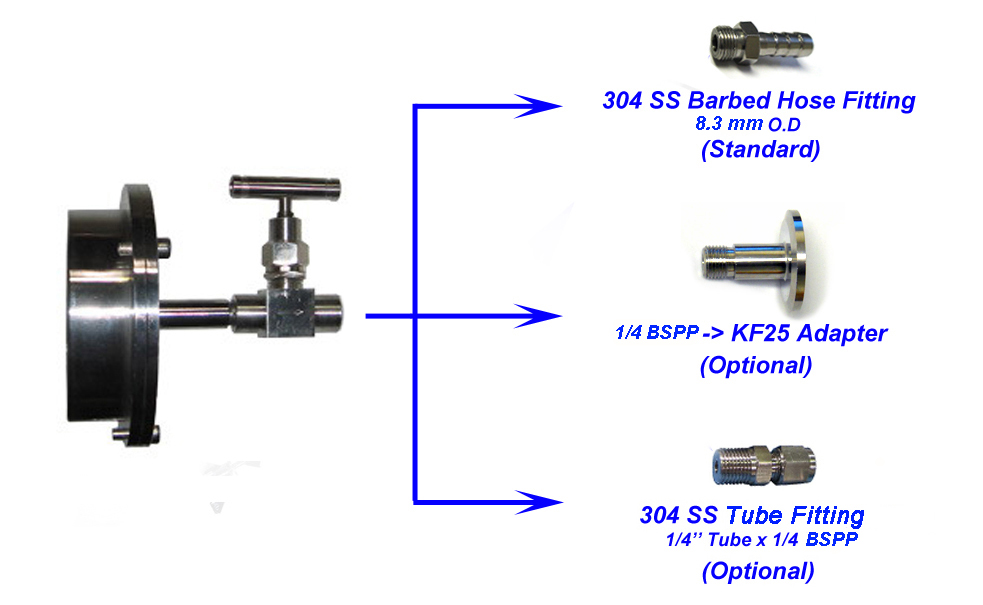

Fitting Ports

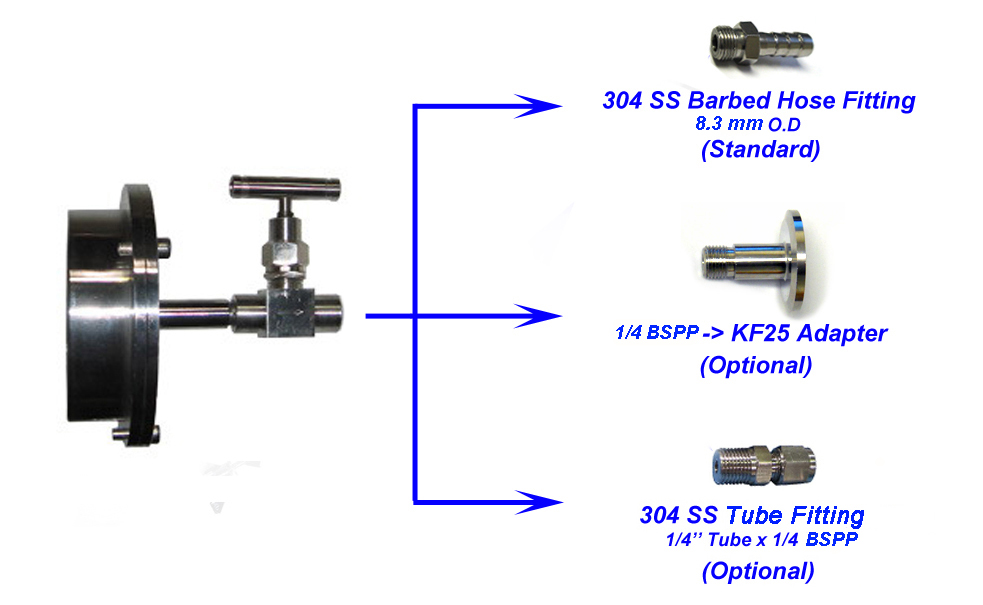

| - Standard 1/4‘’ Barbed fittings with needle valves.

- For supplying high pressure gas, you may replace the standard barbed hose fitting with the 304SS 1/4" Swagelok® Tube Fitting

- Optional: In order to increase the throughput and achieve high vacuum, you may replace the standard barbed hose fitting with the KF25 adaptor.

- Optional: You may also consider using the parts in below to increase the vaccum effeciency

|

Vacuum Level | 0.1 Torr by mechanical pump |

Dimensions | 340mm×300mm×1000mm ( W x L x H) |

Net Weight | about 20 Kg (excluding mobile cart) |

Shipping Weight | 200 lbs |

Warranty | - One year limited warranty (Consumable parts such as heating elements, processing tubes and o-rings are not covered by the warranty, please order the replacement at related products below.)

|

Compliance | 110V version | 220V version |

- CE Certified

- UL / MET / CSA Certification is available upon request, additional charges will apply

- Transformer is UL Certified

| - CE Certified

- All electric parts are UL / MET / CSA certified

- The furnace is ready to pass UL or CSA certification (UL61010 or SPE1000) on customer side at customer cost.

|

|

Application Notes |     |

Warning

Click here to learn the installation of a gas regulator | - Tube furnaces with quartz tube are designed for using under vacuum and low pressure < 0.2 bar / 3 psi / 0.02 MPa

- Attention: A two stage pressure regulator must be installed on gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°C

- The flow rate for gases should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube

|

Premier Solutions Pte Ltd / MTI Corporation - Compact Vertical Split 1"or 2'' Quartz Tube Furnace with SS Vacuum Flanges - OTF-1200X-S-VT