System Structure | |

Three-Zone Rotary Furnace

| - Working temp: 1200ºC Max(<1hrs)., and 1100ºC for continuous heating

- Three digital temperature controllers with 30 segments programmable and +/-0.1 oC accuracy.

- Input Power: 208 – 240VAC, a single phase at max. 4.0 KW.

- The split cover enables faster cooling and easy operation

- Three heating zones: 6"+ 12"+ 6", total 24" ( 609 mm)

- Constant temperature zone: 480 mm length +/-2ºC

- Gear DC motor drives quartz tube with variable speed 2 - 10 RPM

|

Plasma RF Power Supply   | - Output Power: 5 -300W adjustable with ± 1% stability.

- RF frequency: 13.56 MHz ±0.005% stability.

- Reflection Power: 100W max.

- Matching: Automatic

- RF Output Port: 50 Ω, N-type, female

- Noise: <50 dB.

- Cooling: Air cooling.

- Power: 208-240VAC, Single Phase, 50/60Hz

|

Quartz Tube | - One special designed 5'' O.D Fused quartz processing tube is included.

- Please click the pic below to see dimension

|

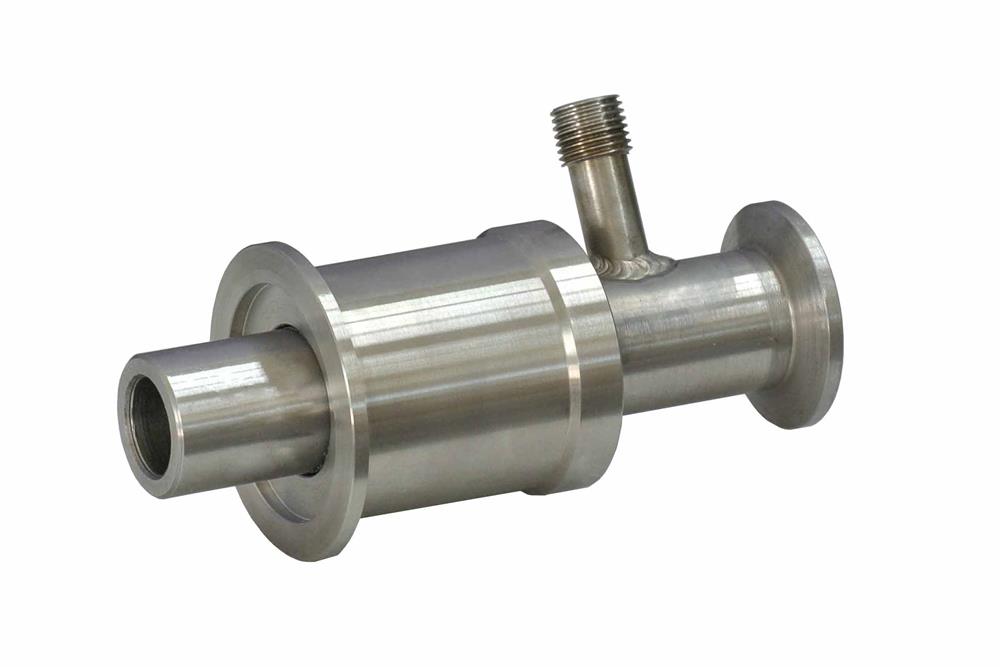

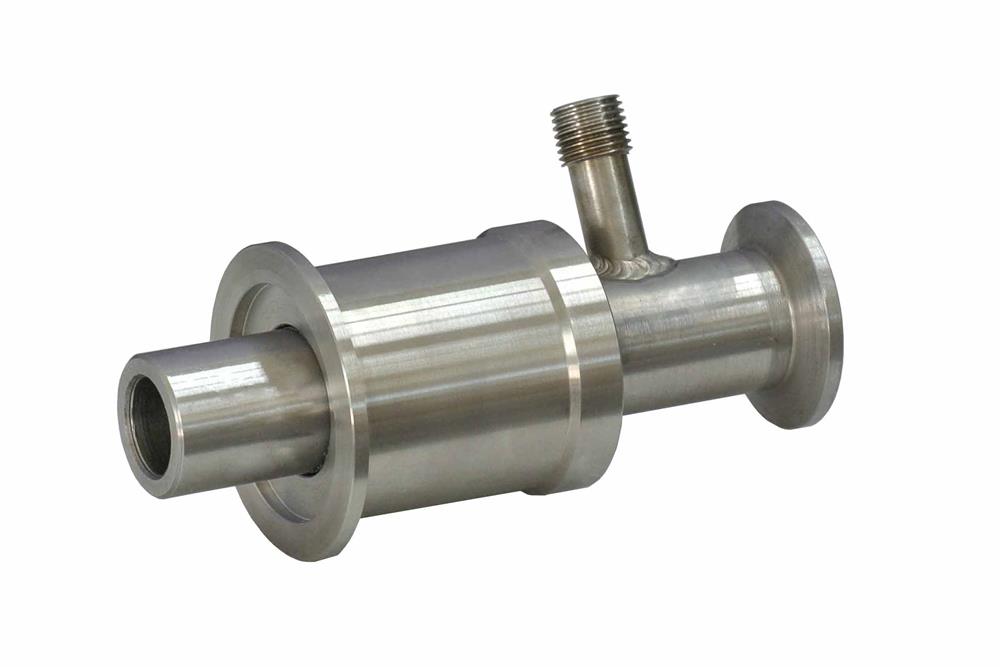

Sealing Flanges   | - A pair of 1'' O.D quick disconnect flange with KF25 port are installed on each end of the tube

- Magnetic fluid seal swivel coupling is used to enable the tube rotation without twisting the fireline or downstream attachments (such as gas, powder and electrical delivery lines)

Left Flange Set Right Flange Set |

Tube Rotation Speed | |

Furnace Tilt Angle | |

Vacuum Pump & Gauge | |

MFC Gas Mixing Station | - Four precision mass flow meters (0.02% accuracy) with digital displays are installed on the bottom case to control gas flow rate automatically.

- MFC 1: Gas flow range from 0~100 SCCM

- MFC 2&3: Control range from 0~200 SCCM

- MFC 4: Control range from 0~500 SCCM

- Gas inlet/outlet fittings: 6mm O.D tube fitting

- Power: 208-240VAC 50/60Hz

- Stainless steel needle valves for manual ON/OFF control of gas supply.

- Large PLC touch screen control enables easy flow rate settings

|

Volumetric Feeder and Collector Tank

Pic.1 Pic.2 | - EQ-PF-1S automatic feeder includes a motor-driven agitator and stainless steel hopper with a built-in vibrator. It is designed for feeding solid powder into a furnace for continuous firing/heat treating with adjustable feeding speed 0 - 97 ml/minute. Please click the pic.1 on the left

- Stainless steel collection tank ( 2 Liter Capacity ) can be installed on the other end of processing tube to gather the fired powder without exposure to air. Please click the pic.2 on the left to see details

|

Dimensions & Weight  | - Furnace: 2800mm L x 800mm W x 1700mm H (with lid opened); Gas Mixing Station: 600mm L x 850mm W x 700mm H; the measurement is measured approximately.

- Net weight: 400 Lbs.

- Shipping Weight: 500lbs.

|

Warranty | One year limited warranty with lifetime support (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order replacements at related products below). |

Laptop, software Control (Optional) | - Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- The software will integrate temperature control, gas MFC control, Plasma control for remote operation

|

Compliance | - CE Certified

- NRTL(UL61010) or CSA certification is available at extra cost. ( please click marks below to learn details )

|

| - The tube furnaces with mullite tube are designed for use under vacuum and low pressure < 0.02 Mpa

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Never heat the furnace while the gas release valve is closed and a positive pressure condition exists within the furnace chamber. The pressure gauge must be used to closely monitor the chamber condition at all times during the heating process; please open the gas release valve immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable damages.

- The flow rate for gasses should be limited to < 200 SCCM ( or 200ml/min )

|

Operation Demo Vidoe | |