Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

5" Rotary CVD Tube Furnace with Three Heating Zones at 1200C Max. - OTF-1200X-III-R5L

Description

The OTF-1200X-III-R5L is a 5" rotary CVD tube furnace with three heating zones built in the NRTL standard. The furnace is especially good for preparing Li-Ion battery cathode and Anode materials with the conductive coating, such as LiFePO3, LiMnNiO3, Si/C, etc. This rotary furnace has a larger tube diameter (5"OD) combined with a longer and more uniform heating area (three zones, 900mm overall length).

(Item number has been updated from OTF-1200X-5L-R-III-UL since March 2019) Specifications:

Furnace Construction |

| |||||||||||||||||||||||||

Heating Zone length |

| |||||||||||||||||||||||||

Processing tube & Flange |

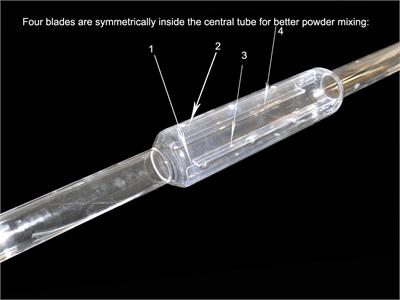

Four Mixing Blades Four Mixing Blades  Dimension Dimension

| |||||||||||||||||||||||||

| Inlet Fitting: Elbow Push-in connector for 6mm O.D tube; Outlet Fitting: Elbow Push-in connector for 12mm O.D tube | ||||||||||||||||||||||||||

Max. Working Temperature |

| |||||||||||||||||||||||||

Temperature Controllers |

| |||||||||||||||||||||||||

Temperature Uniformity | +/- 1°C in heating Zone | |||||||||||||||||||||||||

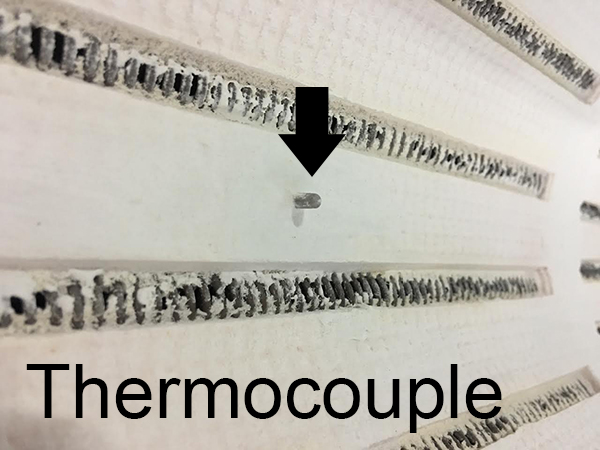

Three Omega K type 3mm OD x 6" L with high-temperature tolerance (220°C) connector | ||||||||||||||||||||||||||

Tube rotating Speed | 0 - 10 RPM variable (Gear reduction ratio 1:150, torque 10Nm) | |||||||||||||||||||||||||

Furnace tilt angle | 0 - 30° | |||||||||||||||||||||||||

Chamber pressure | 10-2 torr | |||||||||||||||||||||||||

Production yield | 2 kg per batch | |||||||||||||||||||||||||

Power | 4 KW Max | |||||||||||||||||||||||||

Voltage | 208 - 240V single phase (30 A Breaker required) | |||||||||||||||||||||||||

| Warranty & Certificate | One year limited warranty (consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, replacements are available at related products below.) | |||||||||||||||||||||||||

| Laptop, software & WiFi Control (Optional) |

| |||||||||||||||||||||||||

| Compliance |

| |||||||||||||||||||||||||

Furnace dimension |

| |||||||||||||||||||||||||

Net Weight | 130 kg | |||||||||||||||||||||||||

Shipping Weight & Dimension |

| |||||||||||||||||||||||||

Operation Video | ||||||||||||||||||||||||||

Application Notes |

| |||||||||||||||||||||||||

Warnings |

| |||||||||||||||||||||||||