Input Power

| - Single-phase 220VAC +/- 10%, 50 / 60 Hz

- 1000 W (including a vacuum pump and water chiller)

- If the voltage is 110 V, a 1500 W transformer can be ordered at MTI (Click the picture to the left for detail)

|

Power Source

| - 13.5 MHz, 100 W RF generator with manual matching is included and connected to the sputtering heads

- Continuous working time:

- 100W: ≤ 1 hour

- 80W: ≤ 1.5 hours

- 70W: ≤ 2 hours

- 60W: ≤ 4 hours

- 50W: ≤ 8 hours

- Load range: 0 – 80 Ω adjustable. Tuning range: -200j – 200j adjustable

- The rotatable switch can activate one sputtering head at a time. Sputtering heads can be switched “in the plasma” (no breaking of vacuum and plasma during a multilayer process)

- With a DC power supply, the coater can be easily modified into 1” DC sputtering sources for metallic film deposition, enabling three DC, one RF / two DC, and two RF / one DC sputtering head configurations (Bottom left picture. Please select from the Product Options)

- Optional 300 W auto-match RF generator is available at extra cost (Click the bottom right picture for detail )

500 W DC Power Supply 500 W DC Power Supply  300 W RF Power Supply 300 W RF Power Supply |

Magnetron Sputtering Head

| - Three 1" magnetron sputtering heads with water cooling jackets (Click Pic #1 for detail information) are included and inserted into quartz chamber via quick clamps

- RF cable replacement can be purchased at MTI (Click Pic #2 for detail information)

- One manually operated shutter is built on the flange (See Pic #3)

- 10 L/min recirculating water chiller is included for cooling sputtering heads (Click Pic #4 for detail )

Pic. 1 Pic. 1  Pic. 2 Pic. 2  Pic. 3 Pic. 3  Pic. 4 Pic. 4 |

Sputtering Target | - Target size requirement: 1" diameter x 1/8" thickness max

- Sputtering distance range: 50 – 80 mm adjustable

- Sputtering angle range: 0 – 25° adjustable

- 1" diameter Cu target and Al2O3 target are included for demo testing

- Various oxide 1” sputtering targets are available upon request at extra cost

- For target bonding, 1 mm and 2 mm copper backing plates are included. Silver epoxy (Pic #1) and extra copper backing plates (Pic #2) can be ordered at MTI

Pic 1 Pic 1  Pic. 2 Pic. 2 |

| Vacuum Chamber | - Vacuum chamber: 256 mm OD x 238 mm ID x 276 mm Height, made of high purity quartz

- Sealing flange: 274 mm Dia. made of Aluminum with high-temperature silicone O-ring

- Stainless steel shield cage is included for 100% shielding of RF radiation from the chamber

- Max vacuum level: 1.0E-5 Torr with optional turbopump and chamber baking

|

Sample Holder

| - The sample holder is a rotatable and heatable stage made of the ceramic heater with stainless steel cover

- Sample holder size: 50 mm Dia. for. 2" wafer max (See picture below)

- Rotation speed: 1 - 10 rpm adjustable for uniform coating

- The holder temperature is adjustable from RT to 600 °C max (5 min max at 600 °C; 2 hr max at 500 °C) with accuracy +/- 1.0 °C via a digital temperature controller

|

| Vacuum Pump | - KF40 vacuum port is built-in for connecting to a vacuum pump.

- Vacuum level: 1.0E-2 Torr with included dual-stage mechanical pump (Click the picture on the left)

- 1.0E-5 Torr with optional turbopump (Click the picture 1-2)

- Vacuum level: 1.0E-2 Torr with dual-stage mechanical pump and 1.0E-5 Torr with the turbopump

- The 1 PPm ga purification system may be used to replace turbopump to get a more clean chamber (Pic.3)

Pic. 3 Pic. 3 |

| Optional | - Precision quartz thickness sensor is optional (Click Pic #1 for detailed information). It can be built into the chamber to monitor coating thickness with an accuracy of 0.1 Å (water cooling required)

- Easy USB connection to PC for remote thickness and coating speed monitoring

- 5 pcs quartz sensors (consumable) are included

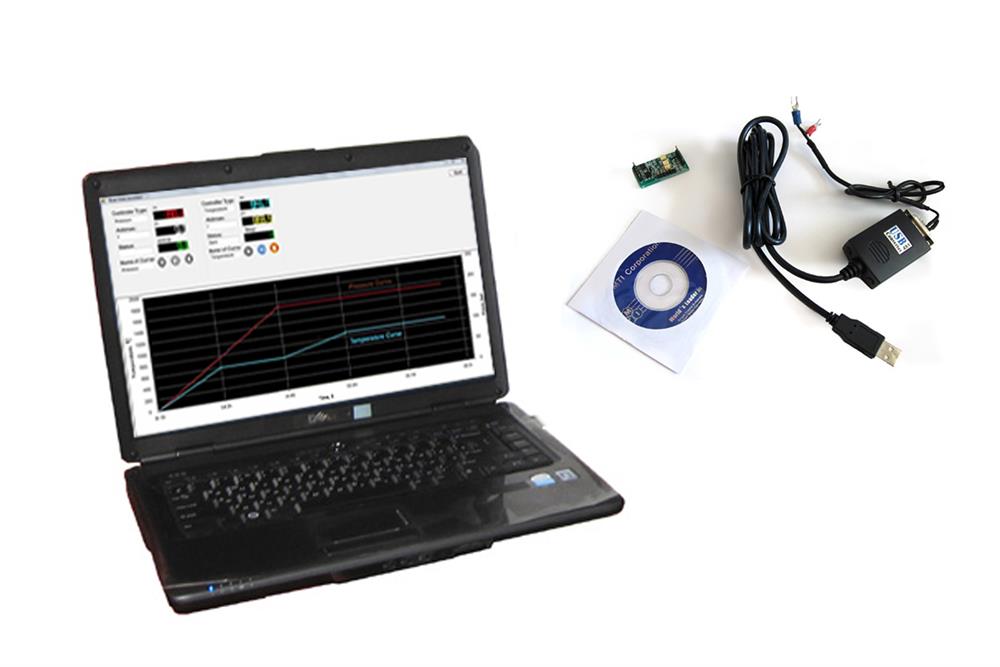

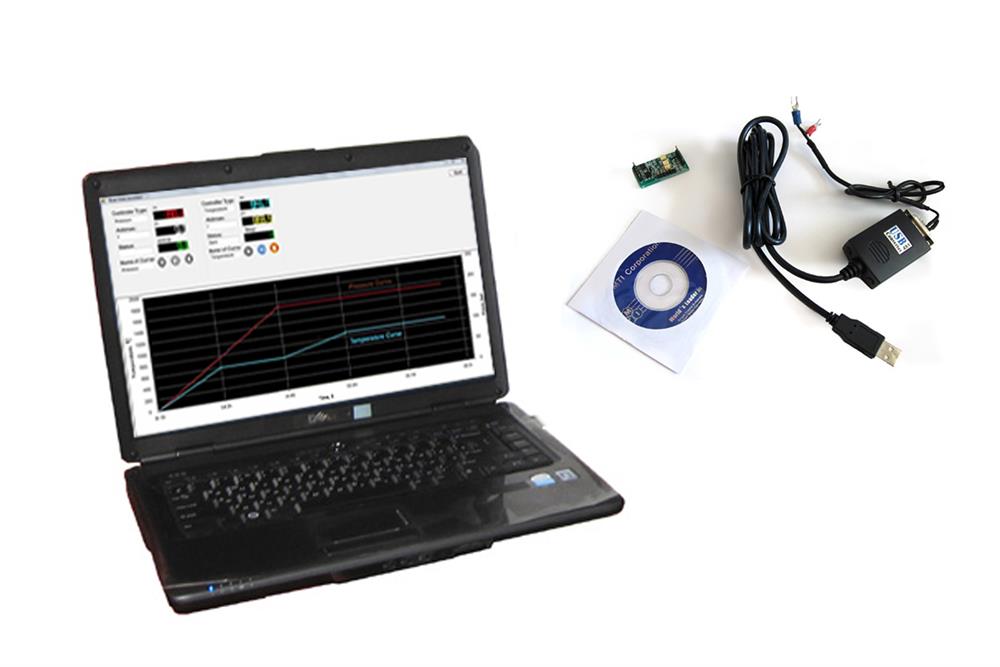

- Remote PC control of the temperature controller is optional (Click Pic #2 for detail information)

- Easy USB connection to PC for remote temperature control

- Temperature control software is included. The module is compatible with LabView

- For DC magnetron sputtering, turbopump is recommended (Pic #3)

- Reactive sputtering with N2 or O2 is available with optional gas mixing control station (Click Pic #4 for detail)

- The coater can be modified into a powder coating (Pictures5)

Pic. 1 Pic. 1  Pic. 2 Pic. 2  Pic. 3 Pic. 3  Pic. 4 Pic. 4  Pic. 5 Pic. 5 |

Size | - 540 mm L x 540 mm W x 1000 mm H

|

Net Weight | |

Compliance | - CE approval

- NRTL or CSA is NOT available temporarily.

|

Warranty | - One year's limited warranty with lifetime support

|

Operation Instruction |   |

Application Notes | - This compact 1" RF magnetron sputtering coater is designed for coating oxide thin films on oxide single crystal substrates, which usually does not need high vacuum set-up

- A two-stage pressure regulator (not included) should be installed on the gas cylinder to limit the output pressure of the gas to below 0.02 MPa for safe usage. Please use > 5N purity Ar gas for plasma sputtering

- For the best film-substrate adhesion strength, please clean the substrate surface before coating:

- Ultrasonic cleaning (Click Pic #1 to order) with the following sequential baths - (1) acetone, (2) isopropyl alcohol - to remove oil and grease. Blow-dry the substrate with N2, then hot bake in vacuum to remove absorbed moisture

- Plasma cleaning (Click Pic #2 to order) may be needed for surface roughening, surface chemical bonds activation, or additional contamination removal

- For best performance, the non-conductive targets must be installed with a copper backing plate. Please refer to the instruction video below (#3) for target bonding

- MTI supplies single crystal substrate from A to Z (Click Pic #4 to order)

- MTI RF Plasma Sputtering Coaters have successfully coated ZnO on Al2O3 substrate at 500 °C (XRD profile in Pic #5)

- HIGH VOLTAGE! Sputtering heads connect to high voltage. For safety, the operator must shut down the RF generator before sample loading and target changing operations

P1 P1  P2 P2  P3 P3  P4 P4  P5 P5 |

500 W DC Power Supply

500 W DC Power Supply  300 W RF Power Supply

300 W RF Power Supply  Pic. 1

Pic. 1  Pic. 2

Pic. 2  Pic. 3

Pic. 3  Pic. 4

Pic. 4

Pic. 1

Pic. 1  Pic. 2

Pic. 2  Pic. 3

Pic. 3  Pic. 4

Pic. 4  Pic. 5

Pic. 5

Pic 1

Pic 1  Pic. 2

Pic. 2

P1

P1  P2

P2  P3

P3  P4

P4  P5

P5