Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

1750ºC Bench-Top Vacuum and Atmosphere Tube Furnace ( 60mm OD) with Kathal Super-1800 Heating Elements - GSL-1750X-60

Description

GSL-1750X-60 is a CE certified compact tube furnace with Kathal Super-1800C Grade MoSi2 Heating Elements and high quality alumina refractory board with ZrO2 liner. Vacuum sealing flanges with valves, vacuum gauge, and a 80mm dia. high purity alumina processing tube are included for immediate use. The temperature of GSL-1750X-60 tube furnace is controlled by a 30 segment programmable high precision SCR (Silicon Controlled Rectifier) digital controller with accuracy of +/-1 ºC. This tube furnace has a max. working temperature up to 1750 ºC. It is widely used in material & chemical researching labs to sinter all types of new material samples under vacuum and other gas conditions.

SPECIFICATIONS

| Furnace Structure |

|

| Power Consumption | Max. 5.2KW |

| Input Voltage | Single Phase, 220V AC, 50/60 Hz (40A breaker required) |

| Working Temperature |

|

| Max. Heating / Cooling Rate | 5ºC / min |

| Heating Zone | 457 mm (18") |

| Constant Temperature Zone | 150 mm (6") |

Heating Elements | Kathal Super 1800C grade heating elements- 330mm L, 8pcs, made in Sweden |

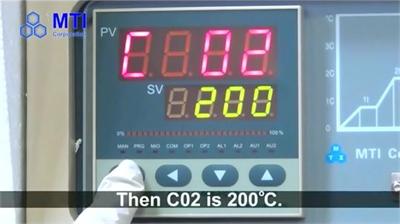

| Temperature Controller |

|

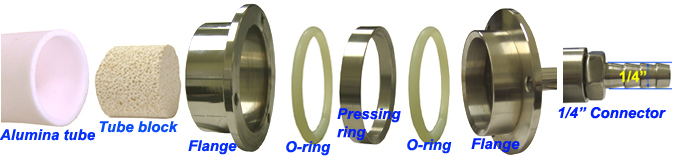

| Tube Materials | High purity Al2O3 ceramic, Purity > 99.9% |

| Processing Tube |

|

| Sealing Flanges |

|

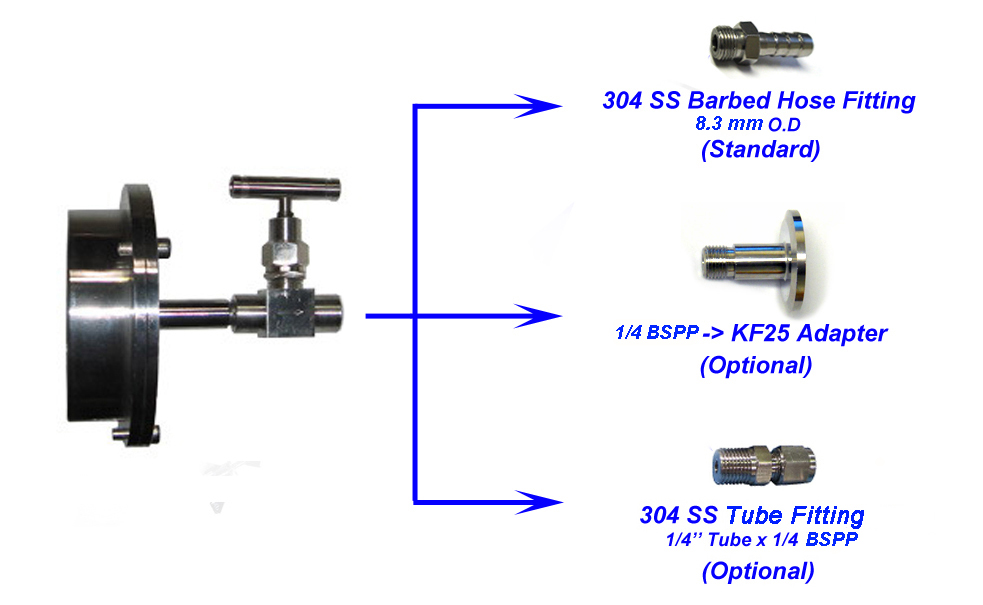

Fitting Ports |

|

| Vacuum Level | Limited by vacuum pump Vacuum pump is not included, please order separately by clicking here |

| Power Cable & Plug |

|

| Dimensions | 590 L x 490 W x 760 H mm |

| Net Weight | 160 kg (352 lbs) |

| Shipping Dimensions | 47"x 45"x 47"(1200L x 1150W x 1194H mm) |

| Shipping Weight | 211 kg (465 lbs) |

| Warranty | One year limited manufacture warranty with life time support (consumable parts such as furnace liner, processing tubes, and O-rings are not covered by the warranty, please order replacements at related products below). |

| Compliance |

|

| Application Notes |

|

| Operation Instructions |