Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

1200C Two Zone 4" Rotary CVD Furnace with Automatic Feeding & Receiving System - OTF-1200X-4-R-II-AF

Description

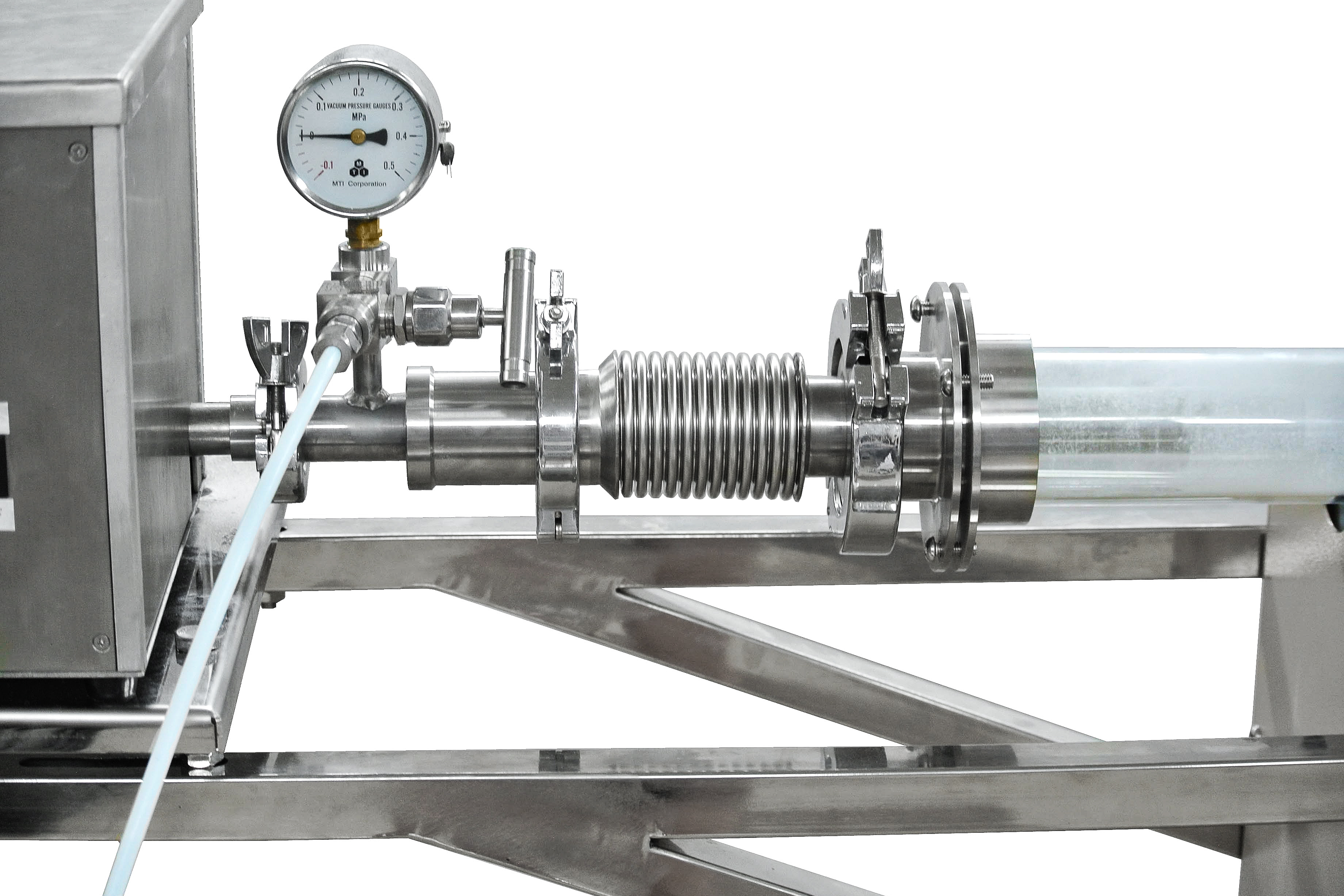

OTF-1200X-4-R-II-AF is a two zones rotary tube furnace with automatic feeding & receiving mechanism. The automatic feeder controls the amount and distribution of the materials inside the tube furnace to achieve continuous CVD powder processing under controlled temperature and atmosphere. The receiving tank will accept fired powder without exposing the material to air.

This furnace set is designed for calcining inorganic compounds with better uniformity and preparing Li-Ion battery cathode materials with conductive coatings, such as LiFePO3, LiMnNiO3, etc and rotating CVD for Si/C anode materials.

* Ref Article:Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries

This furnace set is designed for calcining inorganic compounds with better uniformity and preparing Li-Ion battery cathode materials with conductive coatings, such as LiFePO3, LiMnNiO3, etc and rotating CVD for Si/C anode materials.

* Ref Article:Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries

Specifications:

Furnace Construction |

|

Automatic Feeding Furnace |

|

Heating Zone Length |

|

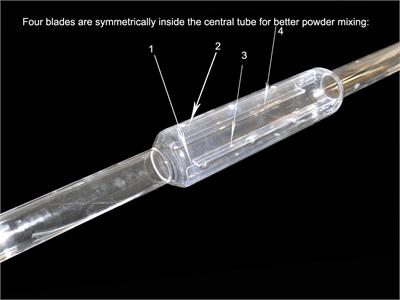

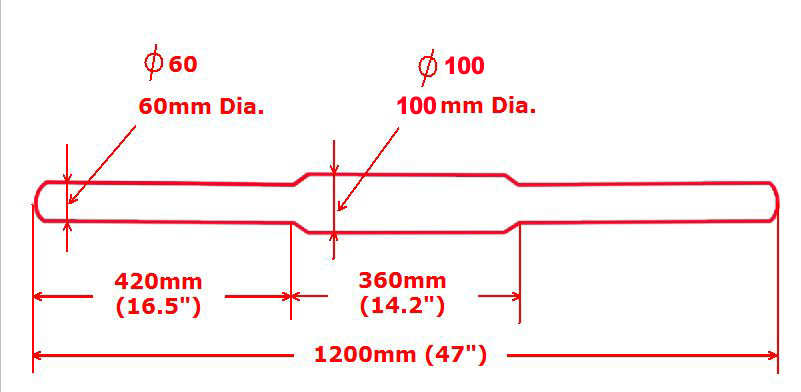

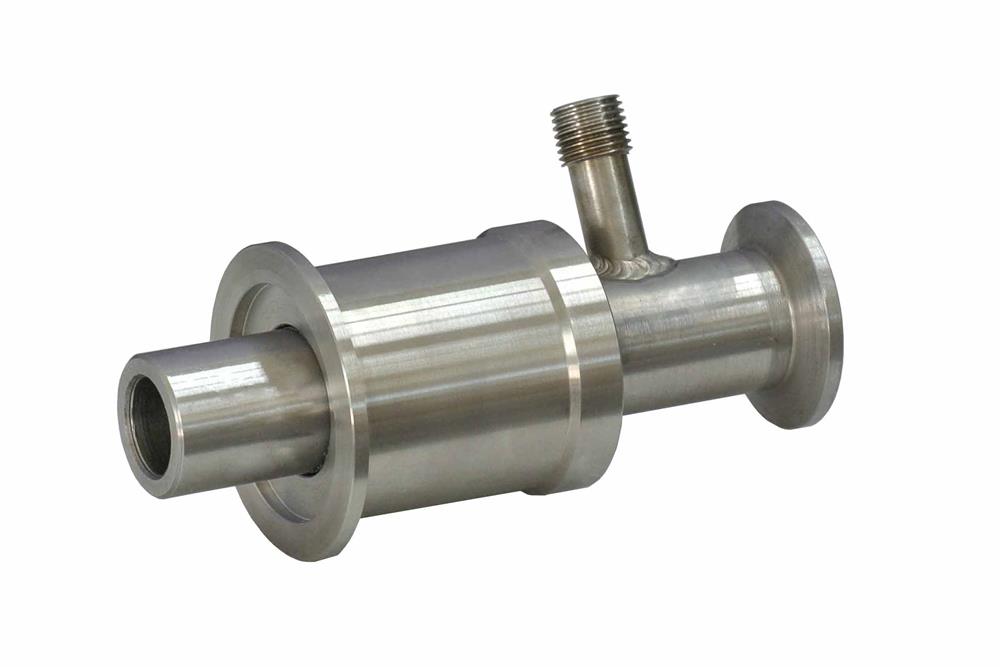

Processing Tube & Sealing Flange |

|

| Max. Working Temperature | 1100°C for continuously 1200 °C Max for < 2 hours |

Temperature Controllers & Thermocouple | Two PID digital temperature controller with 30 segment programmable, +/- 1°C

|

Tube Rotating Speed | 0 - 10 RPM variable |

Furnace Tilt Angle | Left: 0~30° ; Right: 0~15° |

Chamber Pressure | 4.5x10-2 torr (<0.1mtorr/s leaking rate with all valves closed to maximize airtightness of the tube chamber) |

Power | Furnace: 4 KW Max Feeder: 200W Max |

Voltage | Furnace: 208 - 240V single phase (30 A Breaker required) Feeder: 208 - 240V single phase |

| Warranty | One-year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

| Laptop, software & WiFi Control (Optional) |

|

| Furnace Compliance、 |

|

Operation Instructions Video |     |

| Furnace: 1300mm × 600mm × 1200mm Feeder: 220mm × 220mm × 202mm Feeder Hopper Opening: 180mm x 180mm System dimension : 214cm long x 70cm Wide x 153cm High (lid opened) | |

Product Net Weight | Furnace: 200Kg Feeder: 5Kg |

| Shipping Dimension | 65" x 40" x 70" |

| Shipping Weight | 600 lbs |

| Optional |

|

| Application Note |

|

| Warning |

|