Split Tube Furnace | |

Temperature Control | |

Vacuum Sealing | - 2" quick clamp flange with 1/4'' fittings, vacuum gauge as well as needle valve on the right side

- The right flange is connected to a stainless steel bellow which is stretchable up to 150 mm.

- Left flange with quick-clamped KF25 vacuum port and 1/4'' barb venting valve

- Max. Vacuum level: 10E-2 torr by mechanical pump and 10-E5 by turbopump

(click picture to see details ) |

Internal Traveling Mechanism &

PLC Control Pannel

| |

| Max. Heating & Cooling Rate | The max heating and cooling rate can be achieved by moving sample into pre-heated hot zone and move the sample out from the hot zone. The typical ramp/cool rate is listed in below:

Heating Rate: 10°C/sec (150°C - 250°C); 7°C/sec (250°C - 350°C); 4°C/sec (350°C - 500°C); 3°C/sec (500°C - 550°C); 2°C/sec (550°C - 650°C);

1°C/sec (650°C - 800°C);

0.5°C/sec (800°C - 1000°C); | Cooling Rate: 10°C/sec (950°C - 900°C); 7°C/sec (900°C - 850°C); 4°C/sec (850°C - 750°C); 2°C/sec (750°C - 600°C);

1.5°C/sec (600°C - 500°C);

1°C/sec (500°C - 400°C);

0.5°C/sec (400°C - 300°C); | |

|

Optional Parts | - You may need a right angle valve & bellows to connect a vacuum pump ( click the 1st & 2nd pics to order )

- Anti-Corrosive digital Gauge up to 10E-5 torr is optional for CVD application (Pic 3)

- You may order multi-channel gas delivery system for DVD or CVD operation ( Pic 4)

|

Dimensions |  ( click Pic to see details ) |

Warranty | One year limited warranty with lifetime support (Consumable parts such as tubes and o-rings are not covered by the warranty) |

Laptop, software & WiFi Control(Optional)   | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables users to edit temperature profiles, manage heat-treatment recipe, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000). Please contact us for more information.

|

Compliance | - CE Certified

- NRTL or CSA certification is available upon request at extra cost.

|

Warning

| - Tube furnaces with quartz tubes are designed for using under vacuum and low pressure < 0.2 bars / 3 psi

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°C

|

| Operation Video and Instructions |    |

| Application Notes | This multi-functional furnace is suitable for the applications in below:

- RTE: Crucible loaded with evaporation material is placed in the center of the furnace, move sample holder to a downstream position with the appropriate temperature where the deposition takes place.

- HPCVD: Similar setup as RTE, we also introduce reactant gas to mix with evaporation vapor and make a deposition

- Horizontal Bridgman Crystal Growth: Load material and seed into a crucible and place it in the center of the furnace. Move the crucible at the desired speed to grow single crystal under suitable thermal gradient.

- If you have any question and suggestion, please contact us before purchasing

- After CVD, the graphene must be transferred from the metal catalyst to another substrate for most applications. By using the graphene transfer tape, the residue can be low

- For Horizontaldirectional crystalization (HDC), you may use a gas feedtrough as pic below:

|

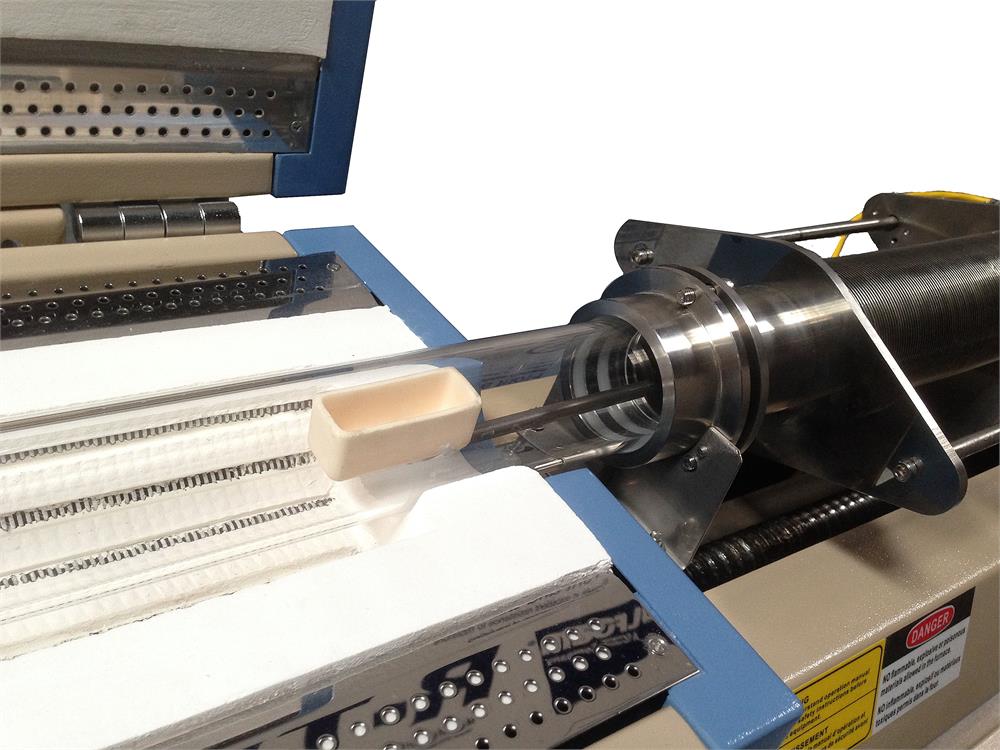

OTF-1200X-S-HPCVD is a compact 2" split tube furnace with internal sample traveling system inside the processing tube. This allows the position & temperature control of the sample stage or crucible via touch screen digital controller. It is designed for multi-functional rapid thermal processing, such as hybrid physical-chemical deposition(HPCVD), rapid thermal evaporation (RTE), and as well Horizontal Bridgman Crystal Growth ( HDC) under various atmosphere for new generation crystal research.

OTF-1200X-S-HPCVD is a compact 2" split tube furnace with internal sample traveling system inside the processing tube. This allows the position & temperature control of the sample stage or crucible via touch screen digital controller. It is designed for multi-functional rapid thermal processing, such as hybrid physical-chemical deposition(HPCVD), rapid thermal evaporation (RTE), and as well Horizontal Bridgman Crystal Growth ( HDC) under various atmosphere for new generation crystal research.

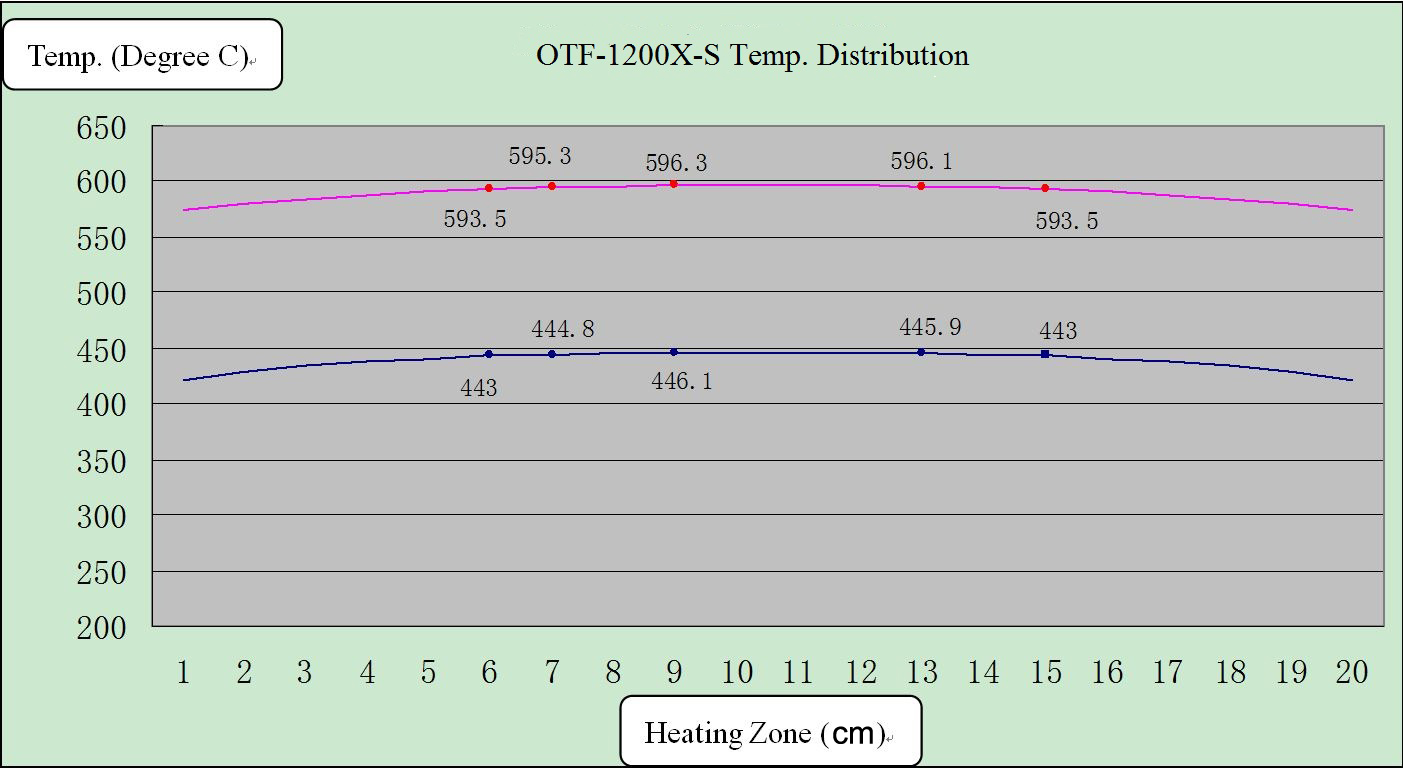

-- two-zone furnace

-- two-zone furnace  (click picture to see details )

(click picture to see details )