Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

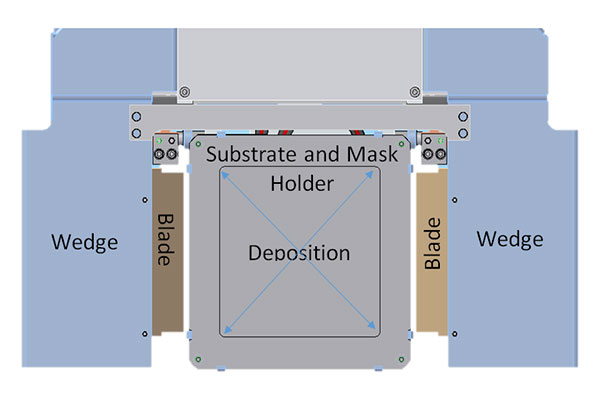

- Super-SPECTROS 200 - Organic Thin Film Deposition & Metallization System up to 200mm x 200mm Substrate

Super-SPECTROS 200 - Organic Thin Film Deposition & Metallization System up to 200mm x 200mm Substrate

0.0/5 rating (0 votes)

Description

Overview

- Optimized for organic material deposition

- Up to 12 LTE sources; 1cc, 10cc or 35cc capacity

- Host to dopant ratio 1000:1

- Up to 4 thermal evaporation sources

- Substrate shutter

- Automatic substrate, mask storage and exchange

- Pyrometer port

- Glovebox interfaceable design with sliding front door and sliding rear door

- KJLC eKLipse™ control software

- Rate control resolution 0.05Å/s

- Recipe based PC based system controls

- Cryopump high vacuum pumping

- 2-position gate valve

Options

- Wedge tool for shaped film growth

- Co-deposition

- Electron beam source

- Twelve source thermal evaporation source array

- Caesium, Selenium, or HTE source

- Load lock chamber

- Plasma clean

- 3-position gate valve

- In-situ source material replenishment

- Substrate rotation, heating and cooling

- KJLC adaptor box and 2-port or 4-port glovebox

- Turbomolecular pumping

- Datalogging

Applications

- Organic Semiconductor

- Nanoscale Devices

- Metal Cathode Deposition

- Organic Films

- Organic Electronics and Photovoltaics (OPV)

- OLED

- OLED Displays

- OLED Lighting

- Organic Electronics

- Integrated Smart Systems

- Thin Film Batteries

- MEMS/NEMS

Specifications

| Process Chamber | UHV grade, 304 stainless steel, nominally 24" wide x 24" deep by 40" tall |

| Framework | Steel construction, enclosed panel base with open chamber access, fully enclosed electronics cabinet |

| Vacuum Pumping | Brooks 1500 l/s cryo pump with oil-free backing pump standard (8x10-8 mbar base pressure) |

| Vacuum Valves | VAT 2-position pneumatic HV valve. Optional VAT 3-position pneumatic HV valve. All others are KJLC HV valves |

| Pressure Measurement | Pfeiffer 685 L/s turbomolecular pump with an Adixen 2010SD oil sealed roughing pump. Base pressure for a properly conditioned chamber is 2 x 10-7 torr (2.67 x 10-7 mbar) |

| Vacuum Interlocks and Venting | Automatically sequenced vent control & vacuum interlock for process chamber |

| Deposition Uniformity | ≤±3% on a 10" (250mm) diameter or 8"(200mm) x 8"(200mm) Si wafer with a 5mm edge exclusion as measured on an AlQ3 or Al film of >200nm thick |

| Low Temperature Source | KJLC design low temperature evaporation (LTE) source for controlled deposition of materials up to 600°C |

| Substrate Platen | Platen for up to 8" (200mm) diameter or 8"(150mm) x 8"(150mm), available with 20 rpm rotation, substrate heating up to 350°C, cooling to -10°C, and RF plasma clean/etch via the substrate shutter. 5-shelf cassette for substrate and mask storage with exchange |

| Film Thickness Control | Film thickness and deposition rate control enabled via system software and controller (no 3rd party hardware required) |

| System Control | KJLC eKLipse™ software PC-based HMI manual computer control, with optional recipe control and datalogging |

| Required Power (Typical, based on options) | 400VAC, 3∅, 32A, 50/60Hz, 5-wire (3Ph+N+E) |

| Compliance | CE, optional CSA and UL |

| Warranty | 12 months upon receipt, extended warranty is available at additional cost |

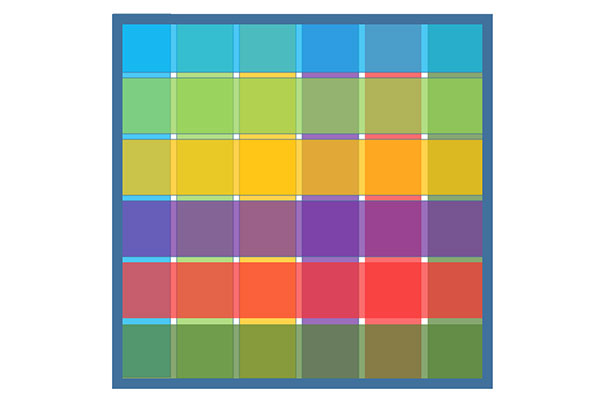

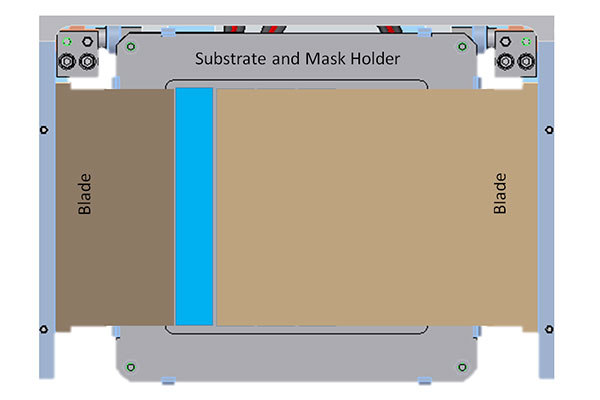

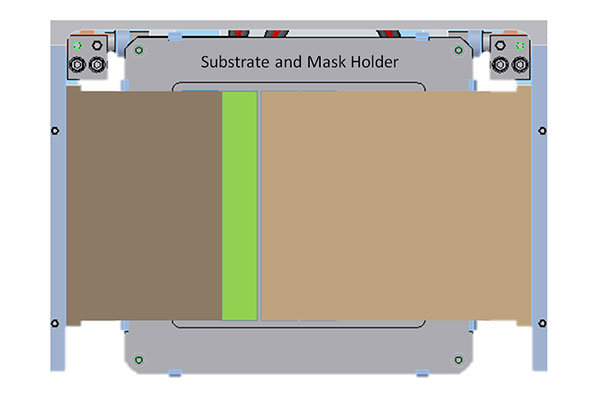

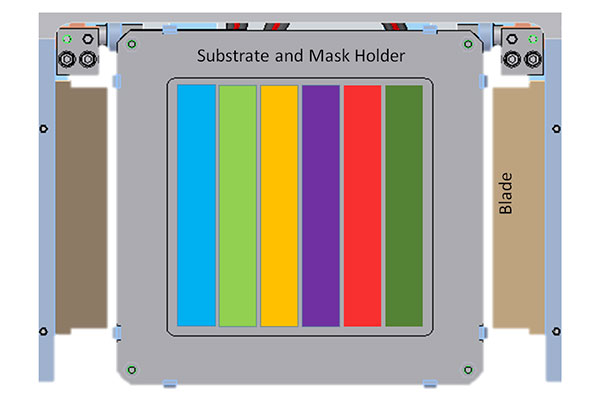

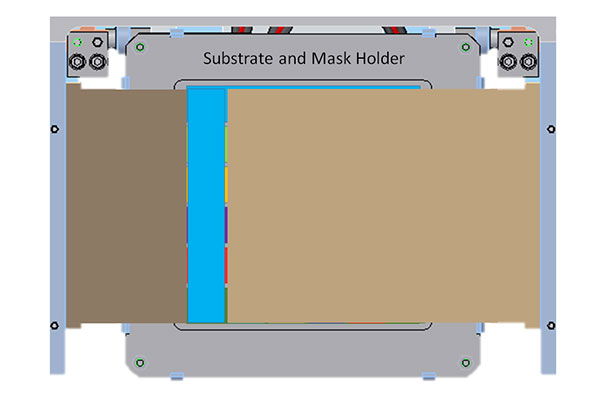

KJLC Combinatorial Dual Wedge Tool

The KJLC wedge tool can help deposited films of material with n number of variations in addition to shadow mask. n is number of columns and its width can be programmed. |  |

| Example: 6 step (or six columns) deposition of various thickness of a "Material" or 6 deposition of different materials of same thickness or various thicknesses |

The substrate can be ROTATED 90, 180 or 270 degrees in the cassette and repeat the above wedge operation. |  |

Share this product

Copyright © 2020 Premier Solutions Pte. Ltd. All Rights Resrved | Address: 100 Tras Street, 100 AM, #16-01, Singapore 079027. Tel: (65)62843818 Sitemap