Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

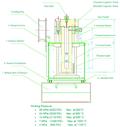

Super-alloy High Pressure Hydro-thermal Reactor 1100C, Optional 65ml & 100ml - GSL-1100X-RC series

Description

RC-Ni is reactor made of Ni-base Superalloy, which has excellent creep strength and anti-oxidation. It can reach 1100 °C with a pressure up to 4Mpa under oxygen or inert gas. It is an ideal tool for preparing advanced material by the hydrothermal method, especially heat treat samples under high oxygen pressure. A solenoid valve is installed on the flange allows auto-pressure relief control. Temp. Control and Pressure Real-time Monitoring software are also included. (new feature since 5/12/14)

SPECIFICATIONS

| Structure |

| ||||||||||||||||||||

| Working Voltage |

| ||||||||||||||||||||

Pressure Vessel  |

| ||||||||||||||||||||

| Product Dimension |  | ||||||||||||||||||||

| Reactor Capacity & Dimensions ( Pls select the volumn in the option bar ) |

| ||||||||||||||||||||

| Working Temperature & Control |

| ||||||||||||||||||||

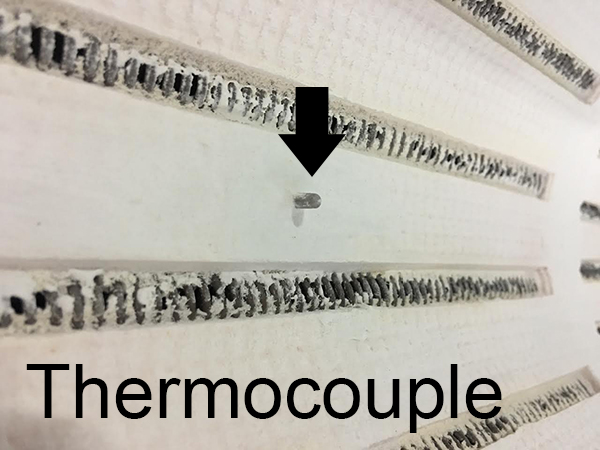

Thermocouple |

| ||||||||||||||||||||

| Working Pressure |

| ||||||||||||||||||||

| Pressure Sensor | Precision high-pressure sensor (measurement Range up to 250 bars) installed on the pressure vessel. | ||||||||||||||||||||

| Pressure Relief Solenoid Valve |

| ||||||||||||||||||||

| PC Control (optional) |

| ||||||||||||||||||||

| Accessories |

| ||||||||||||||||||||

| Operation Instructions |  | ||||||||||||||||||||

| Warranty | One year limited warranty. Consumable parts such as copper gaskets, pressure vessels (if over-pressurized, over-heated or chemical interactions), and heating elements (if overheated) are not covered by the warranty. | ||||||||||||||||||||

| Application Notes |

| ||||||||||||||||||||

| Shipping Dimensions |

| ||||||||||||||||||||

| Shipping Weight |

|