Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

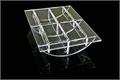

UL-Standard 1100°C 7.6 Liter Hi-Vacuum Chamber Furnace (UL/CSA ready to pass) - VBF-1200X-H8-UL

Description

VBF-1200X-H8 is a CE certified vacuum furnace with a 7.5" ID x 13.4"L quartz tube chamber placed horizontally. Water-cooled stainless steel vacuum flanges with valves are installed to achieve a vacuum of 10-2 to10-5 torr through a mechanical or molecular vacuum pump. It is designed for calcining or annealing semiconductor wafers (up to 6") under vacuum or various other gas atmospheres with a temperature up to 1100°C. It also can also be used as vacuum brazing furnace for fusing small parts.

VBF-1200X-H8 is a CE certified vacuum furnace with a 7.5" ID x 13.4"L quartz tube chamber placed horizontally. Water-cooled stainless steel vacuum flanges with valves are installed to achieve a vacuum of 10-2 to10-5 torr through a mechanical or molecular vacuum pump. It is designed for calcining or annealing semiconductor wafers (up to 6") under vacuum or various other gas atmospheres with a temperature up to 1100°C. It also can also be used as vacuum brazing furnace for fusing small parts.

Power | 3000 W max. |

Voltage | Single phase 208 - 240 VAC / 50/60Hz, (20 A breaker required) |

Working Temperature |

|

Heating Elements | High quality Ni-Cr-Al resistance wire as heating elements and can be heated up to 1200°C. |

Quartz Tube Size & Effective Heating Area |

|

| Vacuum Flange |

|

Digital Vacuum Gauge & KF25 Fitting |

|

Vacuum Pressure | Vacuum Level is dependent on the vacuum pump used, connected pipe, interior refractory block's materials etc. By using KFD25, stainless steel pipe, MTI's two stage mechanical pump and KF25 Ball valve, the furnace can achieve vacuum levels below:

|