Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

1100C Quartz Tube Furnace (2" Dia.) with Temp. Calibrator and Vacuum Pump - GSL-1100X-50-LVT-LD

Description

GSL-1100X-50-LVT-LD vacuum tube furnace is ready to pass UL or CSA certification (UL61010 or SPE1000) on the customer side at customer cost tube furnace for heating samples up to 1100°C. The right side of the furnace system is composed of a KF25 Gas Outlet with Digital Vacuum Gauge connected to Mechanical Pump with Exhaust Filter. The 1/4'' barbed gas inlet on the left, allows the furnace to heat samples in vacuum up to 1E-2 Torr or with flowing gas. In addition, an OMEGA 1/4’’ O.D K Type Thermal Couple is included for attaching to the left flange. It can be inserted into the tube to accurately measure the sample’s temperature by the readout from the OMEGA Calibrator. The built-in precision temperature controller will provide up to 30 segments of heating and cooling steps with +/- 1 °C accuracy.

SPECIFICATIONS

Furnace Structure  |

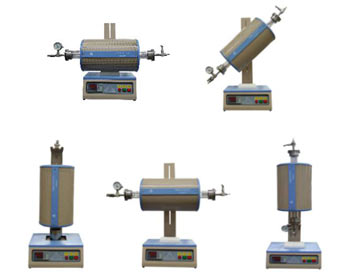

Multi-position adjustable Using as a Vertical muffle furnace Fixing Knobs for Position Adjustment |

| Power | 1500W |

| Voltage | AC 110V or AC 220V 50/60 Hz -- please select the voltage in the option bar |

| Working Temperature |

|

| Heating Rate | Max. Heating Rate: 10°C /min |

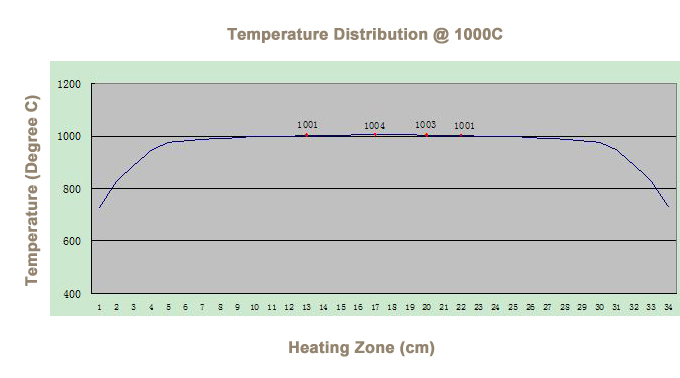

| Temperature Distribution |  |

| Heating Zone |

|

| Temperature controller |

|

Temperature Calibrator | |

| Heating Elements | Fe-Cr-Al Alloy doped by Mo |

| Tube Size and Materials |

|

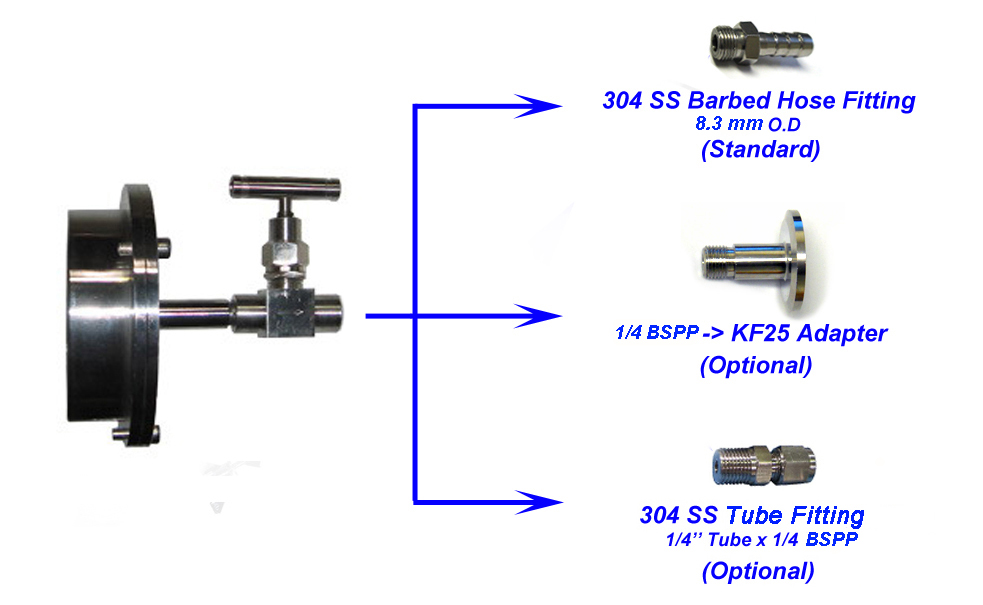

| Vacuum Sealing Flanges | Stainless Steel Vacuum Flanges (Left with 1/4 barb fitting, Digital Vacuum Gauge and Thermocouple feedthrough, right with KF25 port and Right Angle Valve) |

Fitting Ports |

|

| Vacuum Pump and Vacuum Level |

|

| Dimensions | 10" x 15" x 16" (26 x38 x40 cm) (D x H x W) (Click here for details) |

| Net Weight | 100 lbs |

| Shipping Dimensions | 40"(L) x 26"(W) x 35"(H) |

| Shipping Weight | 180 lbs |

| Warranty | One-year limited warranty (Consumable parts such as processing tubes and o-rings are not covered by the warranty, please order the replacement at related products below.) |

| Compliance |

|

| Application Notes Click here to learn the installation of a gas regulator |

|

| Operation Instructions |