Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Mini CVD Tube Furnace with 2 Channel Gas Mixer, Vacuum Pump, and Vacuum Gauge - OTF-1200X-S50-2F

Description

OTF-1200X-S50-2F Mini CVD tube furnace is a CE Certified split tube furnace for heating samples up to 1200°C. A KF25 Gas Outlet and a Digital Vacuum Gauge are installed in the right flange for connection with a 226L/m Mechanical Pump (with Pump Filter). The left flange is used to connect a 2 channel gas mixing station through the 1/4" gas pipe. The precision temperature controller will provide 30 segments of heating and cooling steps with +/- 1 °C accuracy. This furnace system also includes an anti-corrosive Pirani Capacitance Diaphragm Gauge to enable vacuum measurements with aggressive gases. In addition, you can get an accurate pressure reading with any mixed gases via the Digital Vacuum gauge.

| Furnace | Structure | Heavy-duty steel casing Energy-efficient Al2O3 fibrous thermal insulation |

| Power Consumption | 1.75KW |

| Input Voltage | AC110V (For using under AC 220V, please contact our tech. support team) | |

| Temperature | 1200 Max. for < 1hr 1100 for continuously heating Heating rate <= 10C/min | |

| Processing Tube | Quartz tube 50 x 43 x 600mm (O.D x I.D x Length) | |

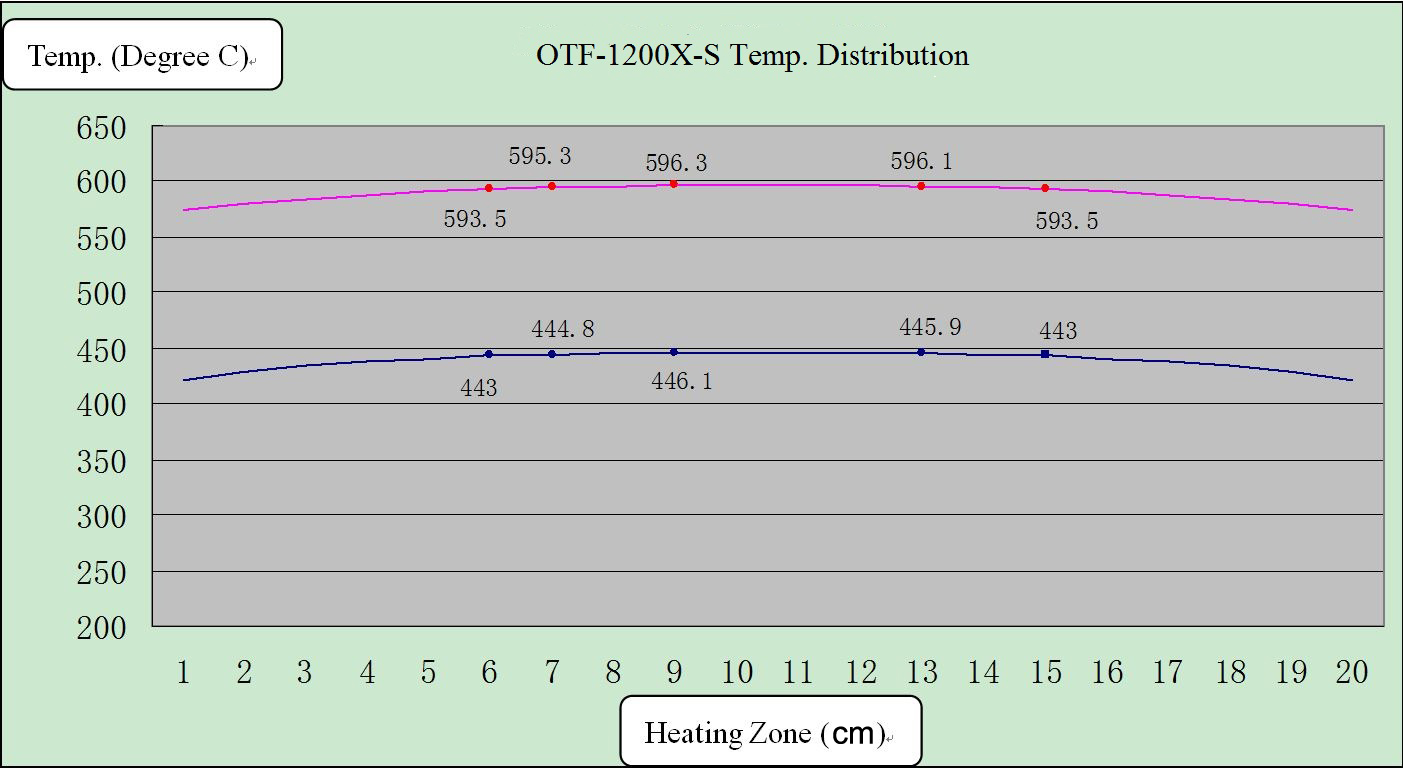

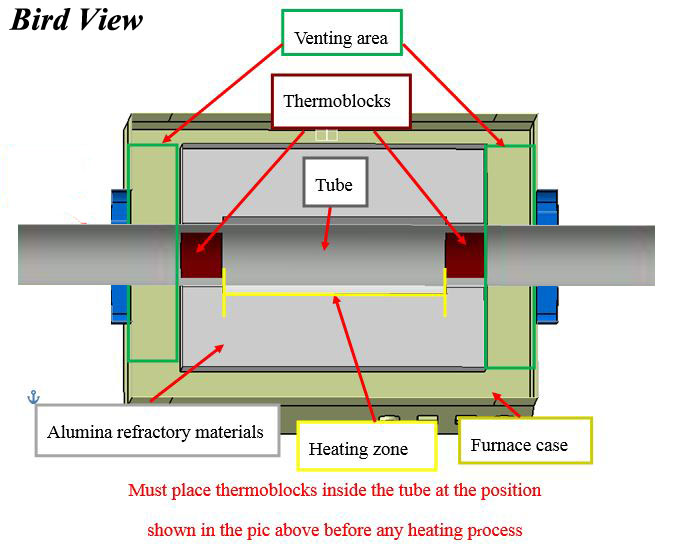

| Heating Zone | Total heating zone length: 8" (200mm); Constant temp. zone: 2.3" (60mm) (+/-1°C) @ 900 °C. The following picture left shows the temp. distribution across the heating zone, please click to enlarge. Two thermal blocks are included and must be placed inside the tube as shown picture below-right   | |

Temperature Controller |

| |

| Heating Elements | Fe-Cr-Al Alloy doped by Mo | |

| Digital Vacuum Gauge |

| |

| Two Channel Gas Mixing Station |

| |

| Vacuum Flanges and Fittings |

| |

Vacuum  |

| |

| Net Weight | 100 lbs | |

| Product Dimensions |

| |

| Shipping Weight | 200lbs | |

| Shipping Dimensions | 45x45x35" | |

| Warranty | One year limited manufacturer's warranty (Consumable parts such as processing tubes, O-rings and heating elements are not covered by the warranty, please order replacements at related products below). | |

| Laptop, software & WiFi Control (Optional) |

| |

| Compliance |

| |

| Application Notes Click here to learn the installation of a gas regulator |

| |

| Operation Video |  | |